Manufacturing systems, connected

Finally, a connected worker platform that’s easy to integrate with other systems.

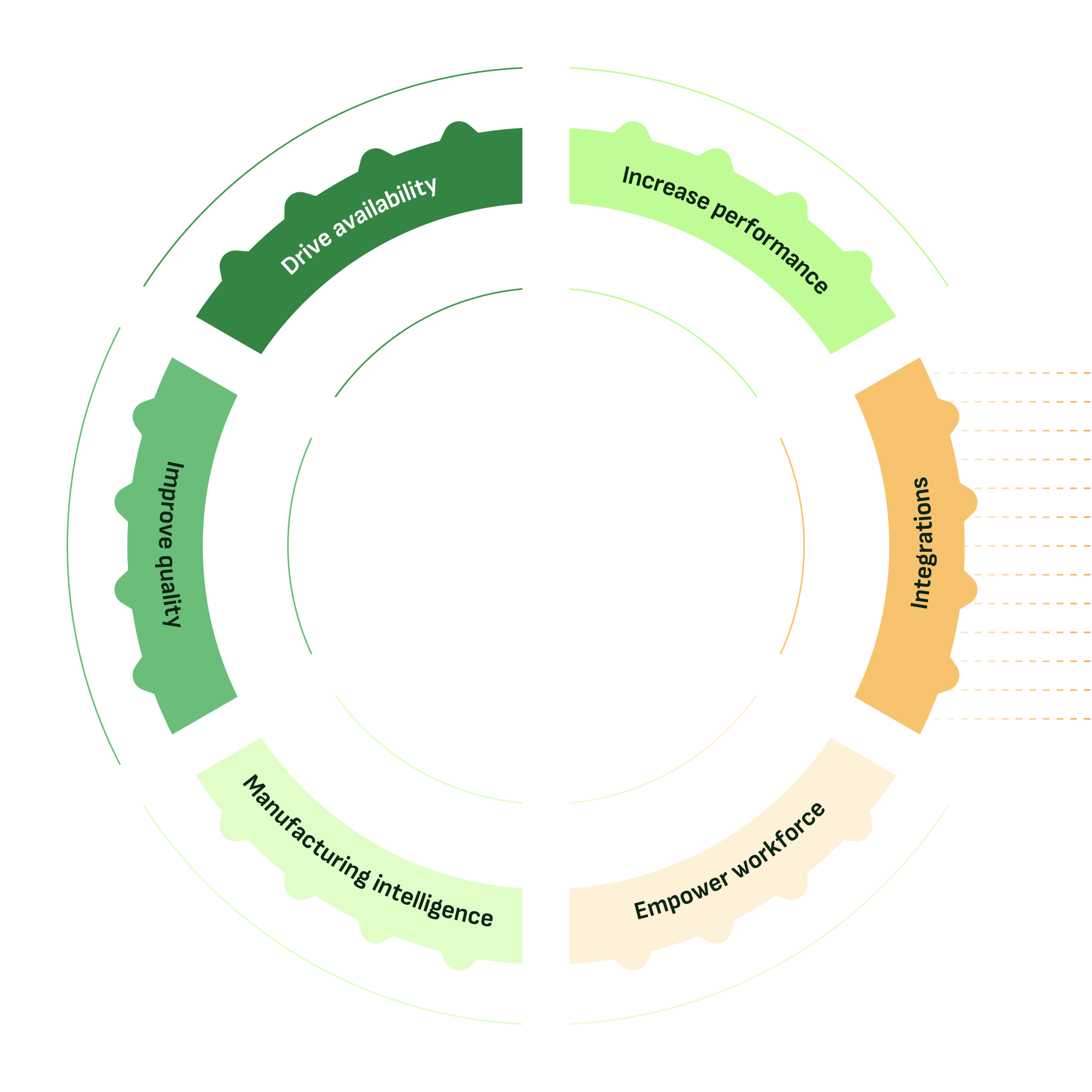

Prevent disruptions by connecting people, tasks, data, and systems in your tech stack.

Track everything that matters

L2L is the connected workforce platform that delivers real insights before, during, and after every shift. Standalone tools can’t connect your people, systems, and data the way we do.

Our platform syncs seamlessly with your ERP, inventory, and production systems to track essential data. Go beyond access to tasks and tools. Drive real connection—and real results.

A unified view of essential information.

Integrate your data with L2L to gain real-time visibility across all functions and improve shop floor efficiency.

ERP

Increase input transparency by syncing spare parts and inventory levels.

MES

Update KPIs, trigger notifications, and enable dynamic scheduling with production and scrap count data.

EAM/CMMS

Eliminate silos and share real-time data with your production teams.

Scheduling

Quickly and easily upload the current production order schedule.

SCADA/OPC

Connect machine-level data with the teams that need it most.

IIoT

Use IIoT data to monitor real-time conditions and trigger condition-based workflows.

BI tools

Export L2L data into your BI solution and merge it with other data for advanced analysis.

And many, many more

QMS, LMS, Safety, EH&S—nearly all industrial data can be integrated with L2L.

Seamless system integration

L2L integrates easily with other systems, including ERP, spare parts, and production orders. Gather the insights you need to prevent disruptions, identify root causes, and improve decision-making.

.png)

Team alignment and visibility

Empower teams to quickly find and fix issues with the same essential information about production actuals, scrap, minor stops, predictive maintenance, orders, and spare parts.

Easy to implement

L2L integrates seamlessly with your existing systems without rip-and-replace. Our standard implementation will have you up and running in 14 to 60 days and deliver value immediately.

Improved decision-making

L2L drives visibility by enabling manufacturers to access data across their existing solutions. Identify bottlenecks, uncover root causes, and improve productivity, efficiency, and quality.

Frequently asked questions

Discover how L2L integrates with your ERP, MES, and other systems. Streamline operations, improve visibility, and drive better decision-making across your plant.

How does L2L simplify data capture?

L2L captures data through multiple methods, including manual inputs from operators via the Operator Portal or Console, automated machine signals, and direct integration with existing systems like ERP and MES.

What types of systems can L2L integrate with?

L2L integrates seamlessly with ERP systems, MES platforms, spare parts inventory, production scheduling tools, and more. This ensures that all your critical manufacturing data flows together into one connected platform.

How fast can L2L be implemented?

L2L’s standard implementation is designed to get you up and running in just 14–60 days, delivering immediate value without the need for rip-and-replace of existing systems.

Does L2L support real-time visibility?

Yes. L2L provides real-time visibility across production actuals, scrap, downtime, minor stops, predictive maintenance, and spare parts. This empowers teams to make faster, data-driven decisions.

How does L2L improve decision-making?

By integrating seamlessly with your existing tech stack, L2L consolidates data from multiple sources, enabling you to identify bottlenecks, uncover root causes, and optimize production in real time.

Can L2L automate maintenance workflows?

Absolutely. L2L supports automated maintenance workflows by connecting asset data to dispatches and escalation protocols, helping teams stay proactive and reduce unexpected downtime.

What makes L2L different from traditional MES solutions?

Unlike traditional MES solutions, L2L is designed for ease of use and rapid deployment. It combines task management, operational insights, and seamless integration into a single platform, eliminating silos and driving connected workforce productivity.

See L2L in action

Discover how L2L integrates seamlessly with your existing systems to deliver actionable insights and prevent disruptions. Ready to transform your operations?