Manufacturing isn’t an industry where companies can stop innovating and still stay competitive. Plants succeed when they stop simply tracking issues and take fast action, even when economic and operational conditions change.

And in 2026, the changes will keep coming.

Ongoing workforce challenges, supply chain volatility, customer expectations for speed and quality, and advancements in AI are forcing manufacturers to prioritize operational resilience.

The companies that pull ahead will be the ones building a connected, agile operating system where people, processes, and production data work together in real time.

Here are the top manufacturing trends in 2026 industrial leaders should keep on their radar—plus what to do about each one.

1. Closing the manufacturing skills gap remains a top priority

For years, manufacturing leaders have been talking about “the skills gap.” Today, they’re treating workforce capability as critical infrastructure.

In L2L’s 2025 Manufacturing Skills Report, 97% of surveyed manufacturing professionals said workforce development is critical for industry resilience. A well-equipped workforce—in terms of knowledge, skills, and technology—is non-negotiable when it comes to hitting production targets.

The skills gap isn’t just “not enough people.” It’s also the reality that most plants are still struggling to train consistently and at scale:

- Only 25% said their training programs are “very effective.”

- Upskilling opportunities beyond initial onboarding were reported by only 48% of professionals surveyed.

Meanwhile, Deloitte reports that the competition for skilled labor remains intense going into 2026. This means that employee retention, which involves investing in upskilling and cross-training, will be a critical priority in the foreseeable future.

What manufacturing leaders should do to address workforce skills in 2026

To address the skills gap and prevent production, quality, and financial losses, leaders must:

- Build training into daily operations (not annual or quarterly initiatives)

- Make learning part of the shift—not simply extra work

- Standardize manufacturing work, then coach against the standard

- Digitize tacit knowledge and make it accessible to frontline employees

Remember: people are the manufacturing industry’s most valuable asset. By investing in their skills and career development, companies will reap the benefits not only in productivity gains but also in lower attrition rates.

2. Repairing shop floor communication becomes non-negotiable

Lines don’t go down because manufacturing employees don’t care. It happens because information isn’t getting to the right people the moment they need it—and it’s exactly why fixing this problem will be a major manufacturing trend in 2026.

In fact, L2L’s 2025 Manufacturing Skills Report found that communication skills made up the top manufacturing skills deficit, reported by over half of survey respondents.

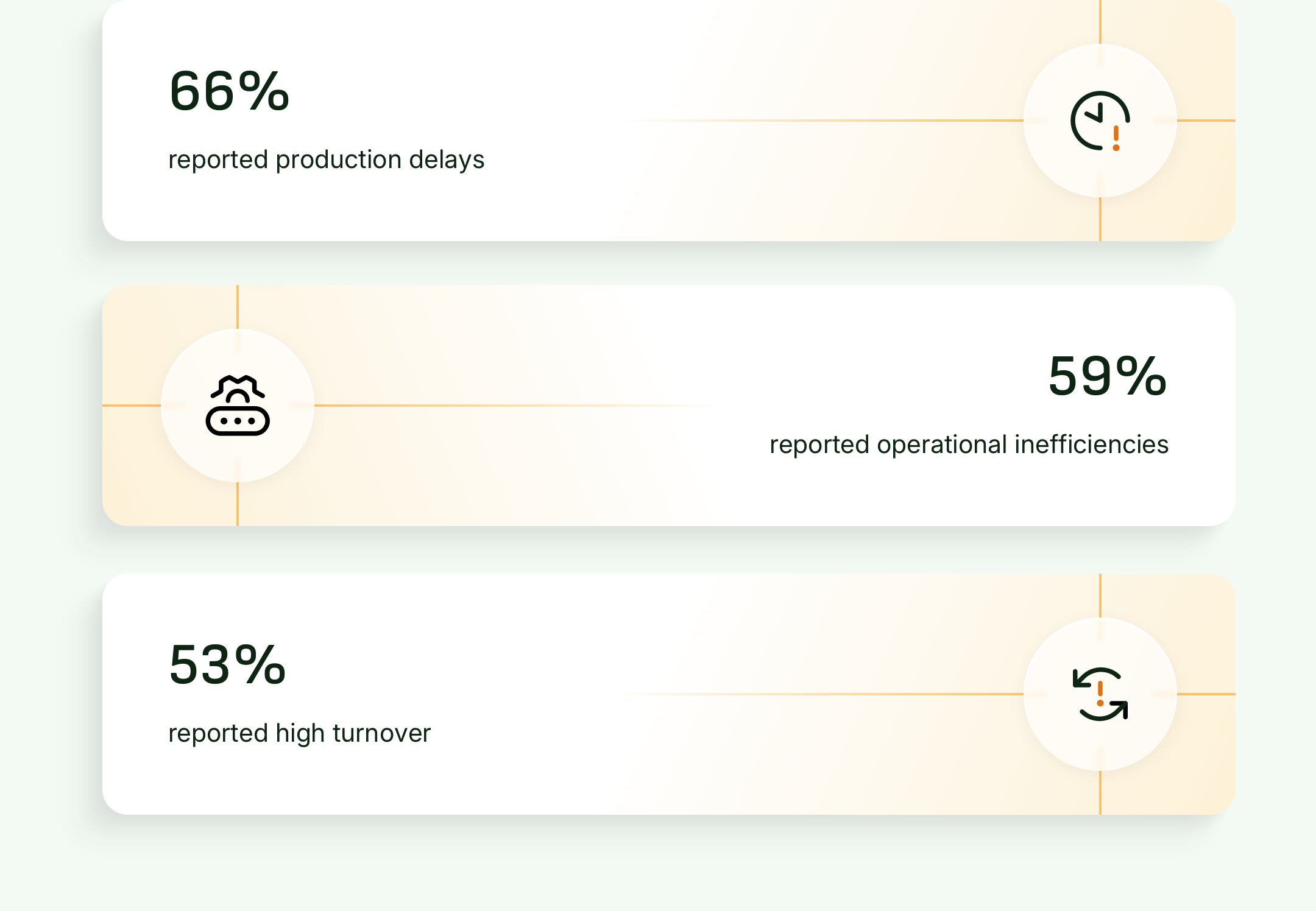

And the operational impact of communication gaps is serious:

Our 2025 report, Beyond Breakdowns, echoes this finding, revealing that 74% of manufacturing professionals see reporting delays slowing down operations.

How leaders can improve shop floor communication in 2026

- Treat communication like a process that has a clear structure

- Develop clear escalation paths (who, when, how)

- Standardize how abnormalities are reported and documented

- Use real-time tools to eliminate “walking the line” to find answers

- Digitize and democratize all job-critical information

Production execution hinges on the workforce’s ability to communicate quickly and accurately. Establishing and maintaining effective communication processes is one of the fastest ways to improve overall operational efficiency—and even labor retention.

3. AI moves from experimental to operationally essential

Industrial AI is no longer an aspiration. It’s an imperative for staying competitive.

In 2026, manufacturers are increasing their investments in AI-driven plant-floor technologies, especially in maintenance, scheduling, quality, and decision-making. Moreover, frontline confidence in AI is rising, with 82% of respondents in one L2L survey saying they feel “at least somewhat prepared” for AI and automation.

Industrial leaders share this sentiment as well. According to IDC, many manufacturers actively use generative AI and agentic AI in manufacturing operational strategy and execution. In fact, a recent survey from Deloitte reports that manufacturers are seeing productivity gains of up to 20% by embracing manufacturing intelligence solutions.

However, most industrial organizations have been slow to adopt AI and smart factory technologies. Without the right data infrastructure in place, it’s incredibly difficult to realize the benefits of artificial intelligence in manufacturing.

How manufacturing leaders should incorporate AI in 2026

- Start with targeted AI use cases, not massive transformations

- Focus on areas of shop floor execution where AI can drive measurable impact fast

- Strengthen foundational data with consistent tags, standardized workflows, and metrics directly tied to shop floor actions

- Build AI governance into processes early (especially for cybersecurity and access control)

If production data is fragmented, reporting is delayed, and downtime causes aren’t consistently captured, AI can’t reliably drive decision-making. Solving the data-readiness problem is a critical first step to making the most of industrial AI investments.

4. Downtime shifts from “fix it faster” to “prevent it systemically”

Unnecessary downtime is still one of manufacturing’s biggest problems, costing the U.S. economy up to $50 billion per year. What’s just as alarming is that approximately two-thirds of manufacturers today still rely on a reactive approach to asset maintenance, according to L2L’s Beyond Breakdowns report.

And the downstream damage is real:

- 57% of respondents said downtime impaired their ability to meet production targets

- 73% reported that downtime had a negative impact on product quality

At its core, excessive downtime doesn’t happen because of mechanical failures. It happens because there aren’t effective systems in place to prevent it—and creating and maintaining these systems must remain a key 2026 focus for manufacturers.

How manufacturers can prevent unplanned downtime in 2026

- Standardize downtime reporting and event tracking processes

- Improve visibility into root causes (not just symptoms) using technologies that connect relevant data and are easy for frontlines to use

- Treat minor stops and adjustments as signals, not noise

- Build preventive maintenance tasks into the daily work management system

- Fix broken communication systems that delay responses to downtime events

To achieve peak uptime (and profitability), leaders must recognize that downtime isn’t only a maintenance problem. It’s a plant-wide issue that requires investment in integrated systems that enable real-time visibility into operational issues before they turn into costly breakdowns.

5. Supply chain volatility inspires agility and transparency focus

Manufacturers have spent recent years strengthening supplier relations and optimizing cost efficiency. But 2026 continues to challenge planning assumptions, especially around tariffs, geopolitical instability, and regional capacity shifts.

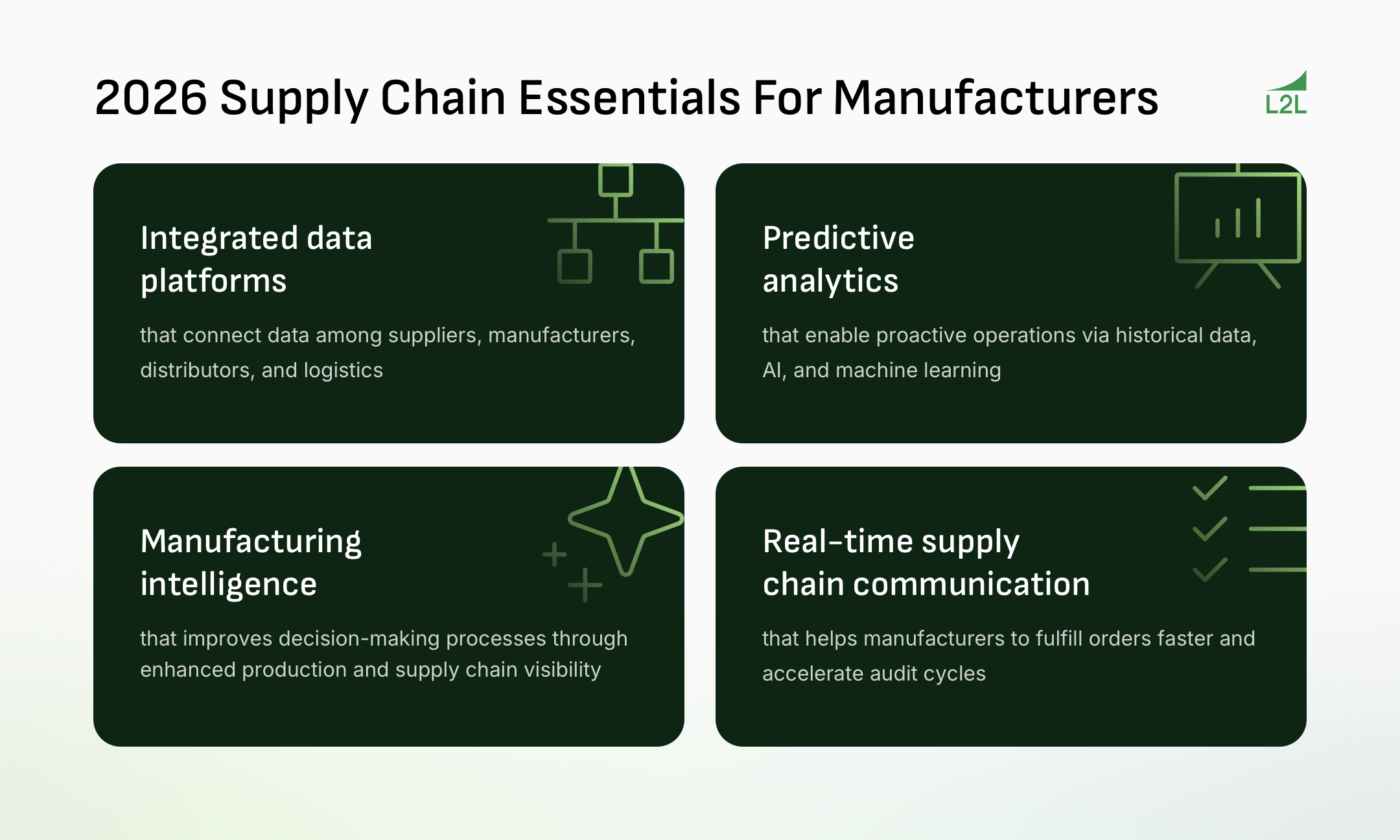

According to Slalom’s 2026 Manufacturing Outlook, manufacturers need more transparent and adaptive supply chains to improve stability and stay competitive. This requires investing in digital technologies that make it easy for manufacturers, suppliers, and customers to collaborate in real time.

Here’s the bottom line: Supply chain resilience increasingly relies on shop floor agility. When materials change, schedules change. When schedules change, labor and execution change. If there’s friction at any point between material changes and execution, disruptions turn into missed output and late shipments.

How manufacturing leaders can strengthen supply chains in 2026

- Improve production visibility so suppliers know what’s happening in real time

- Tighten escalation processes across production, maintenance, and material handling

- Use real-time scenario planning technology to improve contingency planning

- Invest in an agile plant floor: standardized work + fast problem solving beats perfect planning

Ultimately, building supply chain resilience in 2026 demands an integrated, real-time focus on shop floor agility to minimize the impact of external volatility.

6. IT and OT alignment becomes a competitive requirement

To stay competitive in 2026, manufacturers can’t simply digitize processes. They need to connect what’s already digital to create a unified view of operations.

This means closing gaps between IT and Operations. In its 2026 Manufacturing Outlook, Slalom compares this process to weaving a secure “digital thread” through manufacturing departments and systems.

Manufacturing leaders can’t improve what they can’t see, and they can’t scale what they can’t standardize. That’s why it’s crucial for IT and OT departments to align on what needs improvement, KPIs for technical projects, and how much value improvements will generate.

How manufacturers should foster IT/OT alignment in 2026

- Prioritize integration that supports execution (not just reporting)

- Treat cybersecurity as an enabler rather than a blocker

- Build governance that still keeps frontlines fast and mobile

- Standardize operational data definitions across plants

Keeping IT and OT on the same page is the essential next step for manufacturers to unify their operational data, standardize processes, and achieve speed and resilience.

Stay ahead of manufacturing challenges in 2026

To stay competitive in 2026, manufacturers need a way to connect people, processes, and production data in real time so problems can be solved faster and performance improves every shift.

That’s exactly what connected manufacturing operations platforms like L2L are built to support: helping industrial teams improve productivity, reduce downtime, and standardize execution at scale.

It’s time to move faster with fewer disruptions. Book a personalized demo with our digital transformation experts to learn how L2L helps manufacturers achieve operational excellence.

Revisions

Original version: 2 February 2026

Written by: Evelyn DuJack

Reviewed by: Chris Rost

Please read our editorial process for more information

Related Posts

Subscribe to Our Blog

We won't spam you, we promise. Only informative stuff about manufacturing, that's all.