Digital tools for frontline teams.

Drive manufacturing operations forward with unprecedented efficiency. L2L's Connected Workforce Platform gives your teams the digital tools they need to excel. Quickly onboard, train, and upskill while standardizing best practices across all your sites.

Trusted by global manufacturing leaders

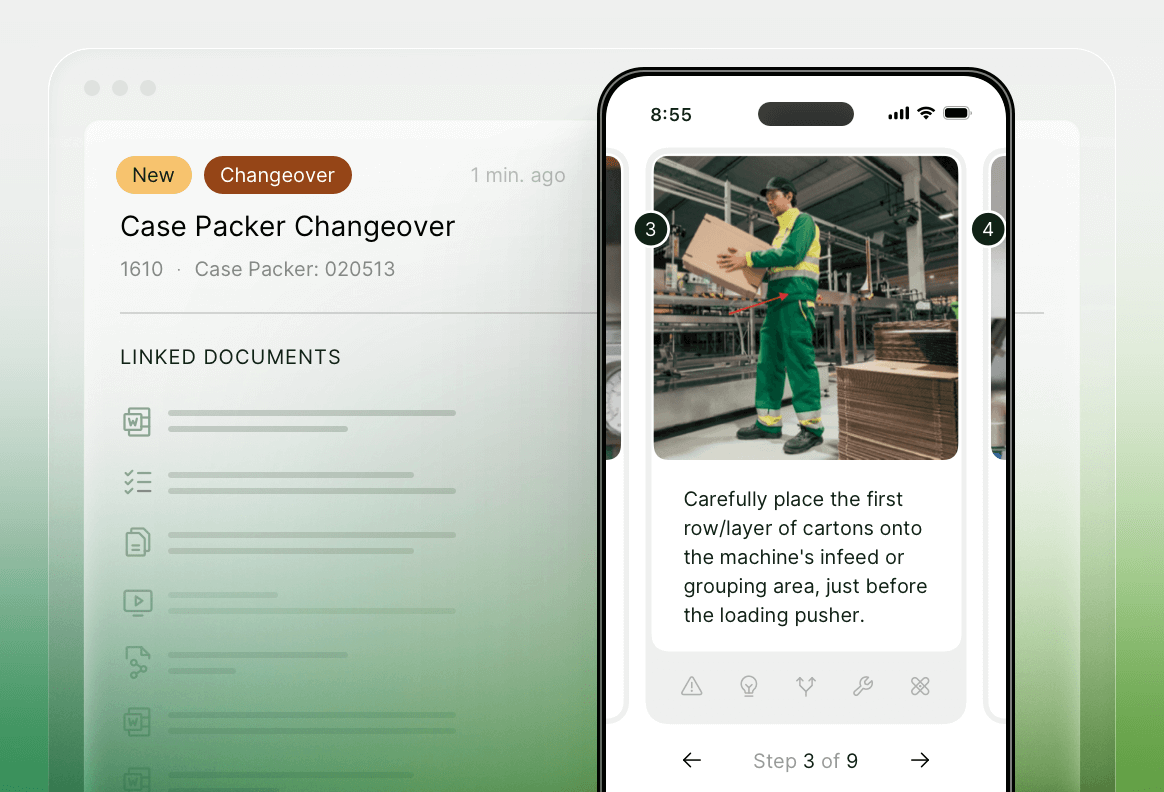

Empower your teams with visual guidance

Move beyond static, paper-based instructions. L2L delivers dynamic digital work instructions directly to your frontlines, ensuring they have immediate access to the latest procedures, visual aids, and critical information. This means greater accuracy, fewer errors, and faster task completion on the factory floor.

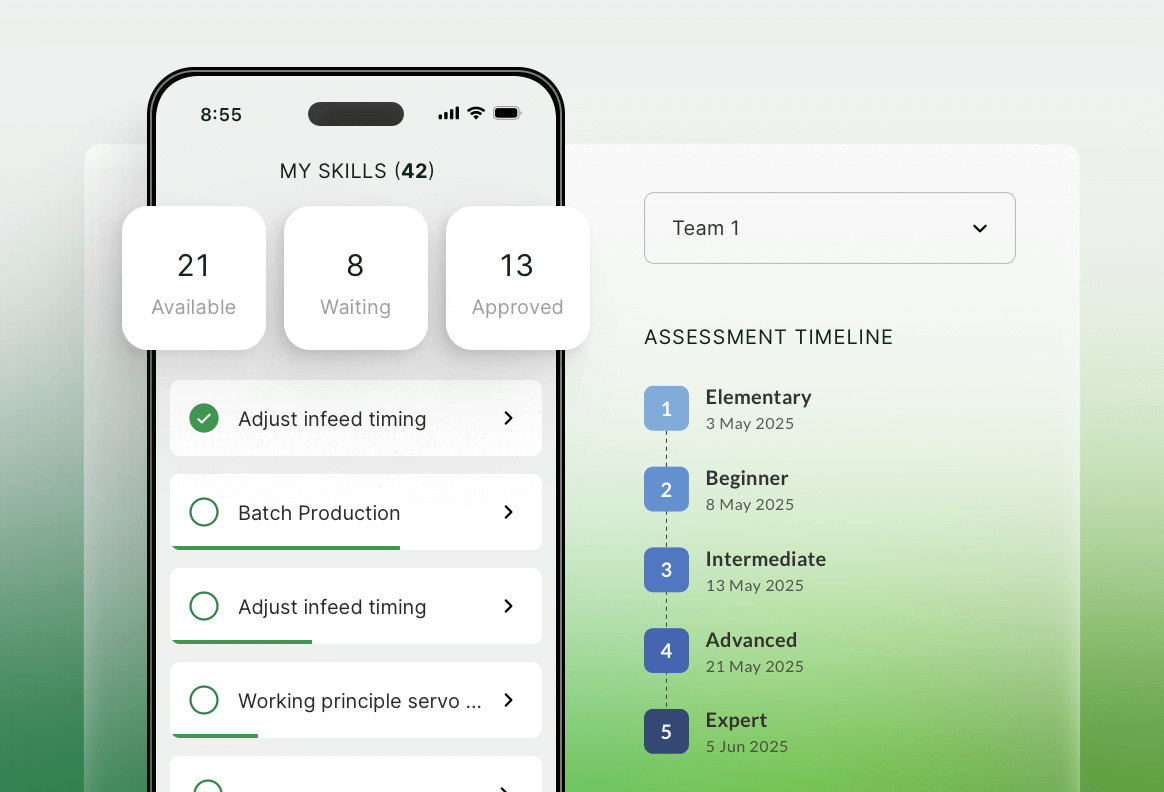

Build a highly capable workforce

Accelerate learning and adapt to new demands. Our Connected Workforce Platform facilitates continuous upskilling and effective training for your manufacturing teams. Deliver effective content, track progress, and ensure your workforce gains the knowledge and skills needed to solve problems and drive productivity forward.

Ensure consistency across all sites

Eliminate variability by enforcing and sharing best practices throughout your organization. L2L allows you to standardize operational procedures across all your manufacturing sites. This ensures consistent quality, compliance, and efficiency, providing a unified approach to excellence, no matter the location.

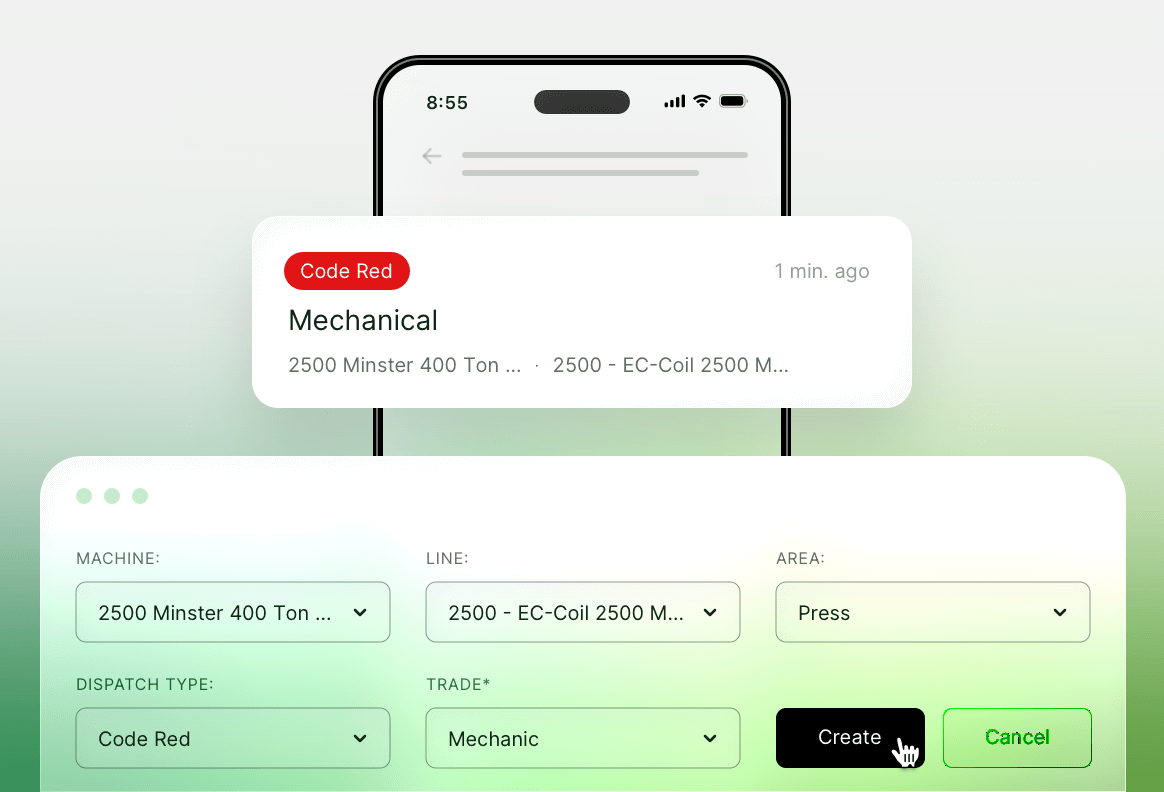

Drive workforce excellence

Unleash your workforce's full power. With our Connected Workforce Platform, you can submit, assign, and resolve production floor issues quickly and correctly on the first attempt to reduce downtime and improve quality.

Connected Workforce Platform ROI

Connected Workforce Platform for Manufacturers

Discover L2L's powerful features and functionalities, designed to streamline your operations, boost team performance, and drive tangible results.

Capture knowledge

Capture and record SOPs, checklists, instruction sets, and more.

Digital work instructions

Follow clear, step-by-step visual work instructions to quickly resolve issues and empower frontline employees.

Sign off

Signal task completion, collect feedback, or check up on skills.

AI-improved text

Ensure what you're saying is clear and actionable to all.

Skills development

Skills-based learning helps frontline teams learn the capabilities needed to perform at their best.

Self assessments

Employees can assess their own skills and get them approved by a manager.

Skills portfolio

Personal skills portfolios offer proof of competence and training.

Skills matrix

Confirm that people have the skills needed to operate a certain machine or process with a dynamic skills matrix.

Career advancement

Empower frontlines to create personal career development paths and reach their goals.

Approval workflows

Make sure content is reviewed by the right people in the right order before it's distributed to frontlines.

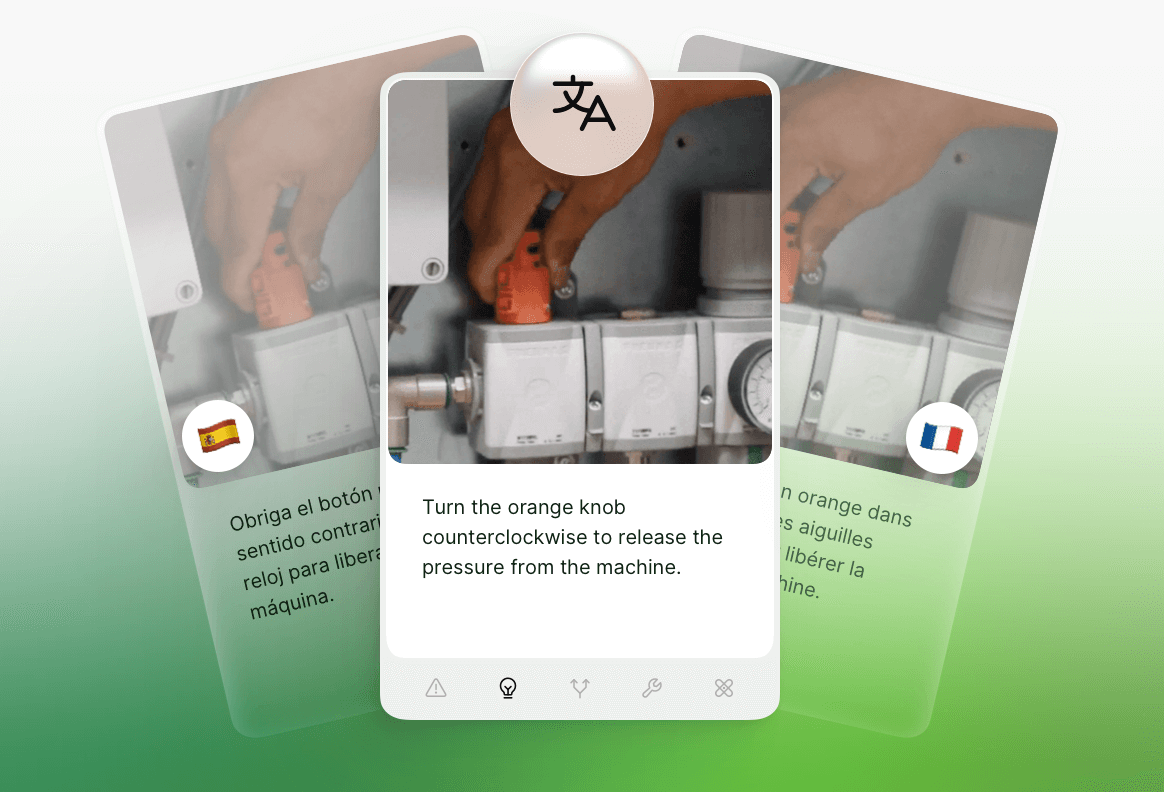

Languages

Easily translate Guides into 47 languages with AI capabilities.

Revision history

Make sure your guides are up-to-date and checked on a regular basis. Set up a standard reminder cycle to ensure your Guides are reviewed periodically.

See it in action!

This is a great tool to make knowledge available on the shop floor. The instructions are easy to use and the user-friendly interface supports knowledge creation by the operators themselves.

Brewery Manager

Having the quality checks helps the line keep running. The operators can go ahead and see how exactly the proper way to do those.

Group Leader of the Packaging Department

The software’s flexibility, checklist feature, analytics, and scalability are added benefits for significant loss elimination.

Quality Assurance Documentation Specialist at Bridgestone

Explore our customer success stories.

Don't just take our word for it, see how other manufacturers are achieving results with L2L.

Frequently asked questions

Can I connect L2L to other systems?

Yes, L2L can be connected to most other systems. Our Technical Services team provides seamless integration setup and maintenance.

How long does implementation take?

We pride ourselves on an efficient, scaled implementation approach. Go-live can happen in as little as a few weeks, so you can begin realizing value from L2L.

Ready to eliminate unplanned downtime?

Move beyond reactive maintenance. Leverage the power of digital maintenance documentation, comprehensive preventive maintenance, and accurate spare part inventory to ensure reliability and maximize uptime.

Start proactively managing your equipment today.

_EasiestSetup_EaseOfSetup.png?width=869&height=1000&name=AdvancedPlanningandScheduling(APS)_EasiestSetup_EaseOfSetup.png)