Optimize uptime & maximize output.

Built by manufacturing experts, our maintenance management software helps you cut downtime and take control of your operations—from managing work orders and preventive maintenance to tracking spare parts inventory—so your plant keeps running at peak performance.

Trusted by global manufacturing leaders

CMMS built by manufacturing experts for manufacturers.

L2L is more than a typical CMMS (Computerized Maintenance Management System). It centralizes your plant operations so you can manage downtime tracking, maintenance activities, production goals, and frontline knowledge and skills. Drive continuous improvement with comprehensive data.

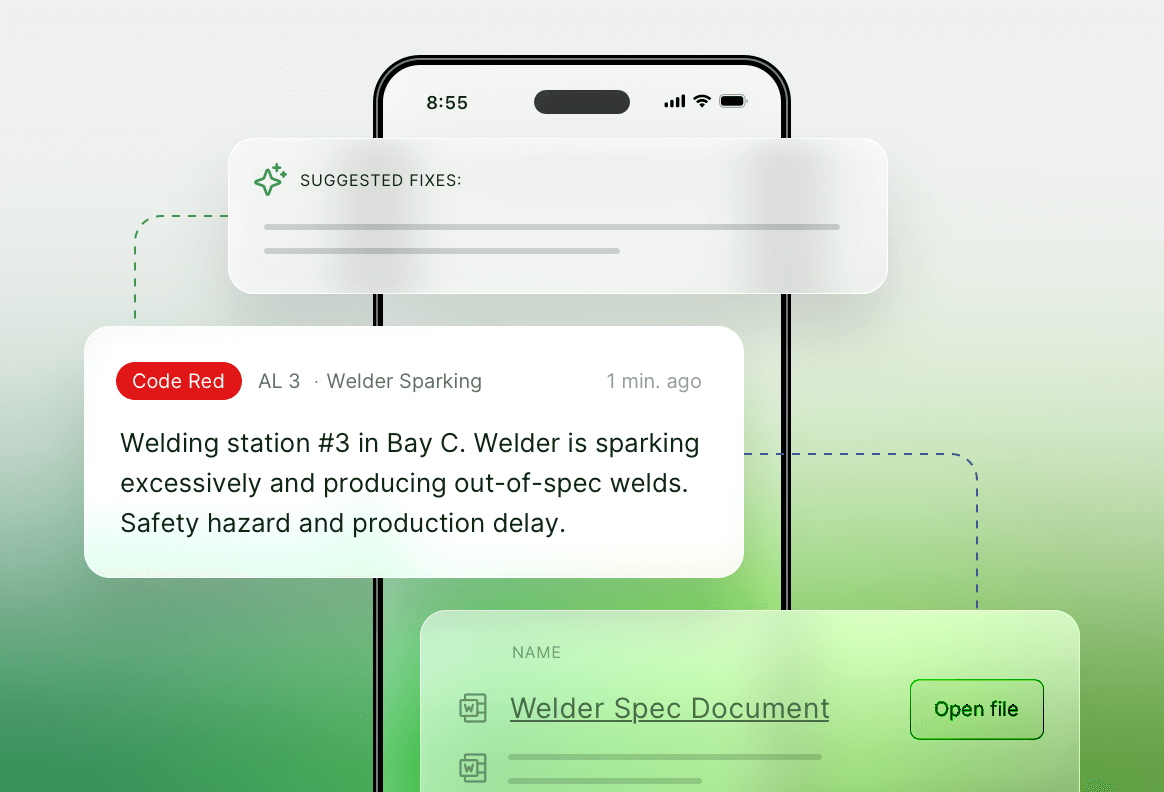

Quickly resolve production disruptions

Get real-time notifications when a problem occurs or an asset goes down. Easy access to visual instructions, asset history, and suggested fixes empowers technicians to solve problems with speed and accuracy.

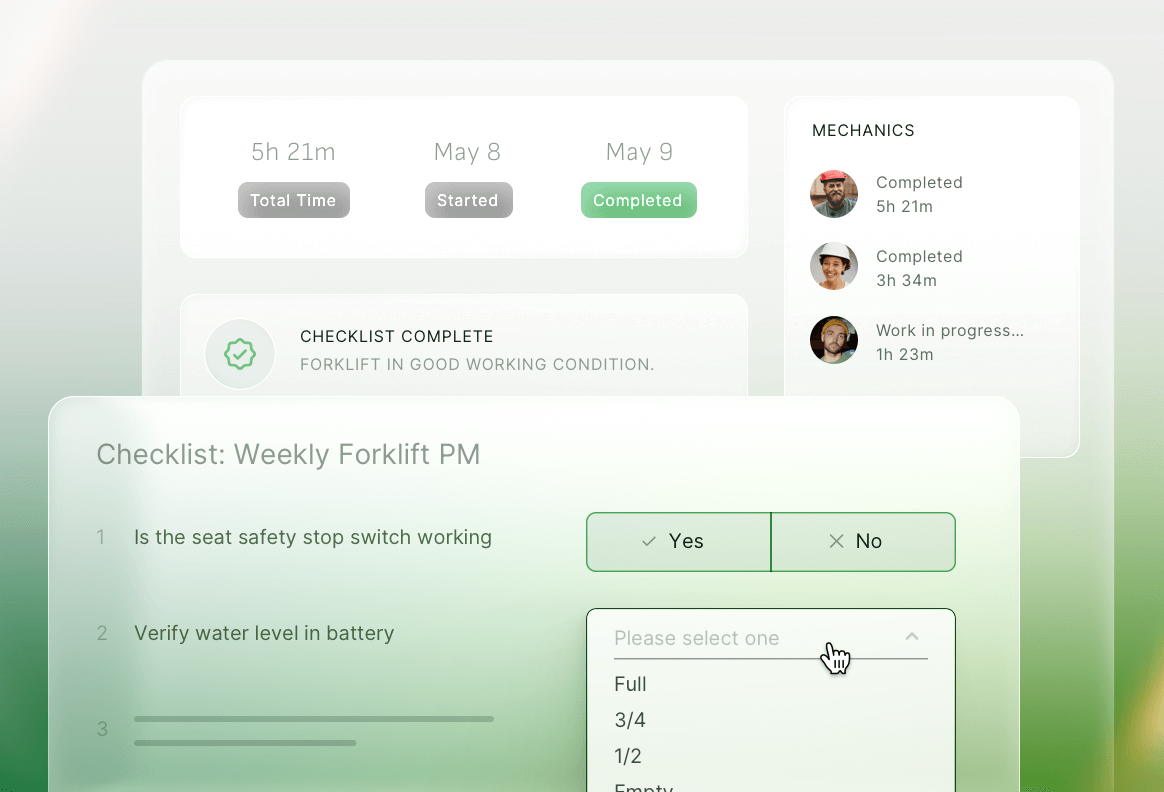

Maximize uptime with

preventive maintenance

Proactively minimize production disruptions and costly asset breakdowns by scheduling preventive maintenance based on time or cycles to maximize production capacity, stay compliant, and extend equipment lifespan.

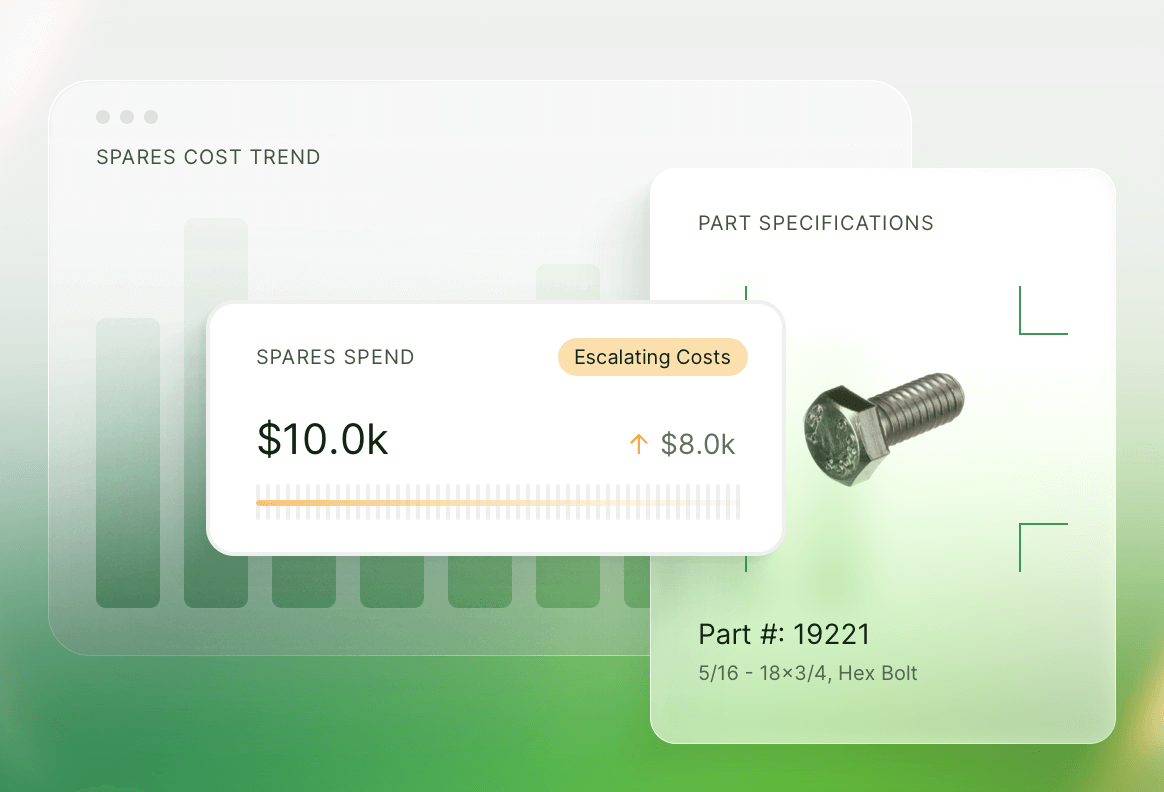

Reduce costs with accurate spare part inventory

Maintain optimal inventory with detailed tracking capabilities and low inventory notifications. AI-powered recommendations speed resolution times and boost accuracy. Strategically right-size your inventory and ensure that parts are always available when needed.

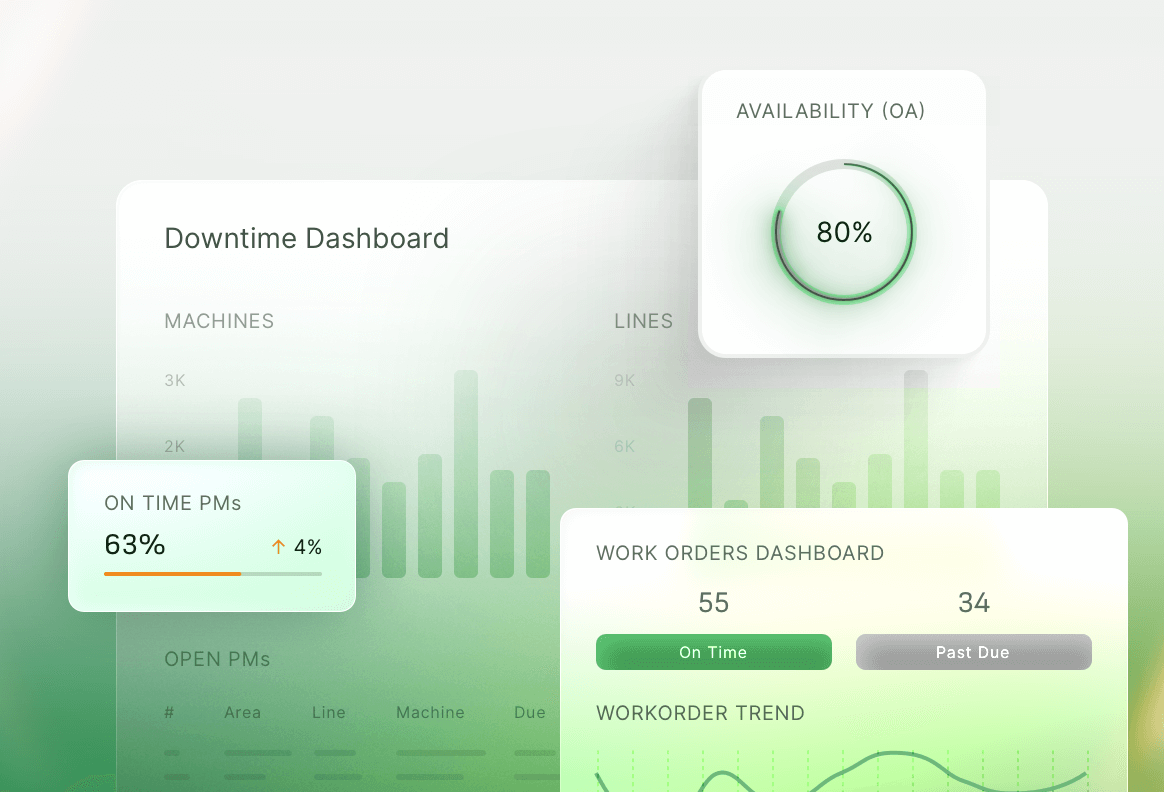

Transform data into meaningful results

Make smarter, faster decisions with a centralized history of maintenance, performance, and failures. Proactively identify issues and optimize strategies with trend analysis. Ensure compliance through a clear audit trail of all maintenance activities.

Manufacturing Maintenance Software ROI

Dispatch issue resolutions

Reduce downtime with immediate production issue reporting. Centralized data lets you automatically alert the right people with the right information for rapid issue resolution.

Work order management

Plan work around production and maintenance schedules to maximize equipment availability and minimize disruptions.

Preventive maintenance

Schedule routine and preventive maintenance based on time intervals or equipment usage cycles.

Digital work instructions

Follow clear, step-by-step visual work instructions to quickly resolve issues and empower frontline employees.

Digital checklists

Create custom digital checklists for various operational processes to eliminate paper-based forms and ensure best practices are followed.

Document management

Keep critical documents like PDF manuals, Gemba Walk reports, and product drawings in the same place and accessible to the right people.

Suggested fixes

Intelligent AI capabilities will suggest correct spare parts or resolutions based on previous correct fixes.

QR codes

Get instant access to equipment-specific history, data, and documentation via QR code scanning.

Spare part tracking

Use a centralized system for managing spare part details like cost, images, machine association, min/max quantities, and location.

Real-time notifications

Streamline communication and ensure employees receive real-time notification of ongoing issues.

Data-driven insights

Make data-driven decisions by recording and tracking key metrics or KPIs.

Machine history

Document and store all equipment history, including repairs, spares, BoM, and more.

See it in action!

Improved machine reliability

Actionable data and dashboards showcase machine availability and improve accountability across the plant.

Better maintenance data

"We've been able to quantify our costs to a different level - with how much a problem costs us with downtime, missed execution on a line, and spare parts."

- Jeremy Morrison, Transformation Analyst at Worthington Industries

From a maintenance standpoint, we are connected to everything on the production side now. We have a lot of information at our fingertips, and it makes us more productive in the things that we do.

Engineering Manager

L2L is a one-stop shop. It reports your production, safety, maintenance, and quality. Everything we need from a day-to-day plant perspective as far as data and information, it's available in L2L.

Operations Manager

The move from paper-based production recording methods to an integrated cloud-based system ensured the right people were at the right place at the right time.

Vice President of Quality

L2L offers data at an extremely intuitive level. It’s actionable data. The report structures are so easy to manage that it allows for very easy determinations of cause and effect around failures.

TPM Implementation Leader

Explore our customer success stories.

Don't just take our word for it, see how other manufacturers are achieving results with L2L.

Frequently asked questions

What is a CMMS in manufacturing?

A maintenance software system, specifically a CMMS (Computerized Maintenance Management System) in manufacturing, serves as a central hub for all upkeep activities concerning equipment and machinery. Leveraging maintenance software, organizations can efficiently manage work orders, schedule preventive maintenance tasks, oversee spare part inventory, and systematically collect crucial operational data. This centralized management of equipment through CMMS software is vital for optimizing asset lifecycles and streamlining maintenance operations within the manufacturing sector.

What are the benefits of using maintenance management software in manufacturing?

- Enhanced Equipment Uptime through Proactive Management: Implementing maintenance software allows for the strategic scheduling of preventive maintenance on critical equipment. This proactive management approach minimizes unexpected downtime and maximizes the availability of essential manufacturing assets, directly impacting production efficiency.

- Streamlined Work Order Management for Efficient Operations: A CMMS centralizes the creation, assignment, tracking, and completion of work orders. This efficient management of maintenance tasks, facilitated by the software, ensures timely repairs and upkeep, reducing delays and optimizing operational flow within the manufacturing environment.

- Optimized Spare Part Inventory Management for Cost Control: Maintenance software provides robust tools for tracking and managing spare part inventory. This improved management helps manufacturing facilities avoid stockouts that can lead to downtime, while also preventing overstocking, ultimately controlling inventory costs associated with equipment maintenance.

- Data-Driven Insights for Informed Decision-Making: The software captures valuable data related to equipment performance, maintenance activities, and work order history. This data-driven approach empowers management in manufacturing to make informed decisions regarding asset lifecycle, resource allocation, and the effectiveness of preventive maintenance strategies.

- Improved Regulatory Compliance and Documentation: Comprehensive maintenance records, easily managed within the CMMS software, ensure adherence to industry regulations and standards within the manufacturing sector. The system facilitates the organized documentation of all work performed on equipment, simplifying audits and demonstrating a commitment to safety and compliance.

Can I connect L2L to other systems?

Yes, L2L can be connected to most other systems. Our Technical Services team provides seamless integration setup and maintenance.

How long does implementation take?

We pride ourselves on an efficient, scaled implementation approach. Go-live can happen in as little as a few weeks, so you can begin realizing value from L2L.

Ready to eliminate unplanned downtime?

Move beyond reactive maintenance. Leverage the power of digital maintenance documentation, comprehensive preventive maintenance, and accurate spare part inventory to ensure reliability and maximize uptime.

Start proactively managing your equipment today.

_EasiestSetup_EaseOfSetup.png?width=869&height=1000&name=AdvancedPlanningandScheduling(APS)_EasiestSetup_EaseOfSetup.png)