Built for automotive manufacturers

L2L's Manufacturing Operations Platform helps automotive companies meet demand with one connected system that enables agile production and maintenance. Shift from reactive to proactive decision-making, eliminate unplanned downtime, and drive global operational excellence.

Trusted by global auto parts manufacturing leaders

.png)

L2L is the connected, intelligent operations platform

Digitize processes, eliminate barriers, and decide with data. That's automotive manufacturing agility.

Unprecedented production agility

Navigate production demands with ease. Real-time data enables rapid adjustments and bottleneck elimination to minimize downtime, maximize output, and respond to rapidly evolving market demands.

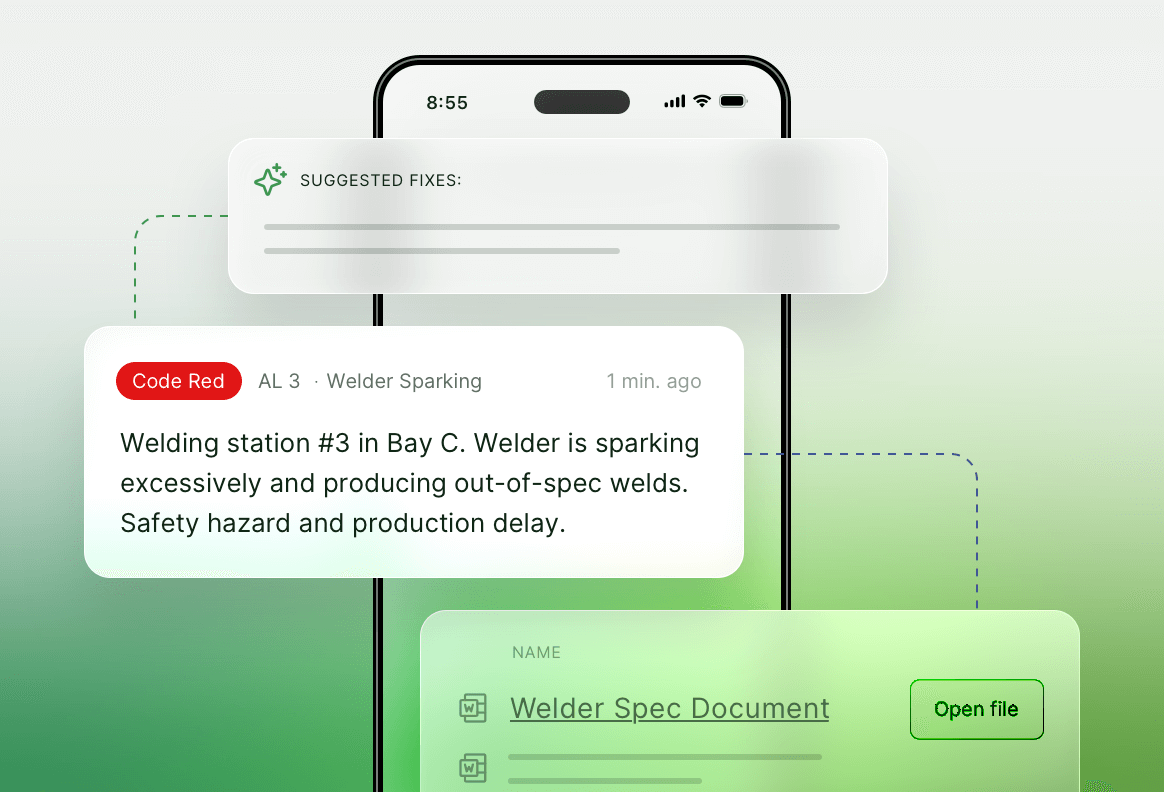

Comprehensive maintenance and production

Eliminate unplanned downtime with comprehensive and connected maintenance tools and workflows. Unite maintenance and production teams for seamless issue escalation, visibility, and rapid resolution. AI recommendations ensure first-time right fixes to drive continuous improvement.

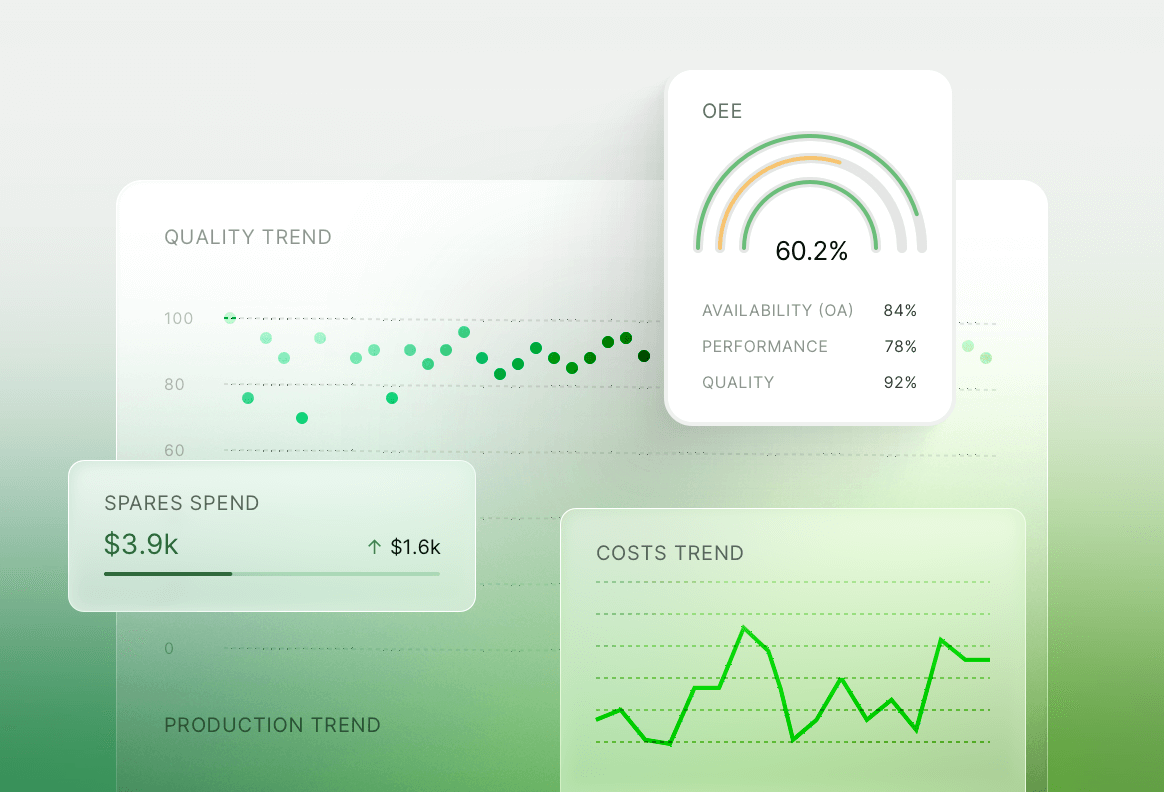

Achieve optimal efficiency

Optimize your automotive operations for efficiency. Highlight areas for improvement with historical and real-time data. Use actionable insights to make better, smarter decisions while streamlining processes to meet profitability goals.

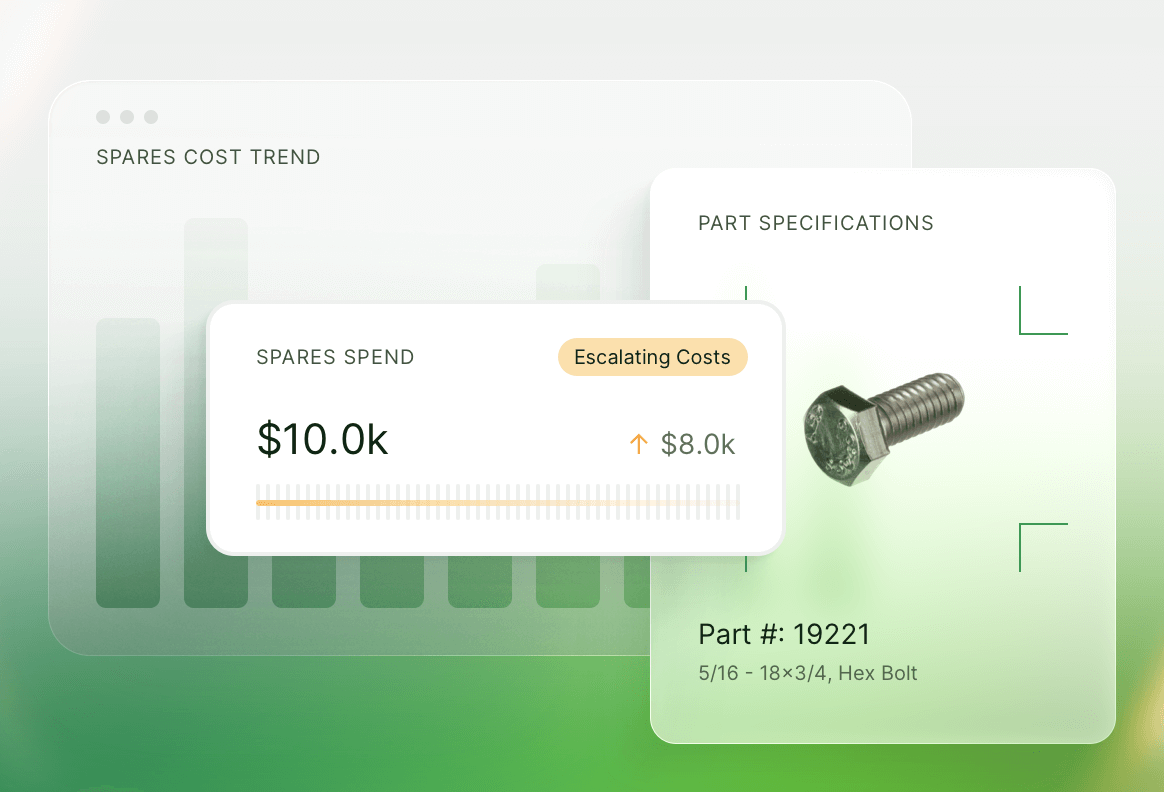

Minimize supply chain disruptions

Maintain optimal inventory stock levels, track part details, warranties, and record consumption. Get notified when inventory is low. Use data to rightsize inventory and ensure you always have the parts you need on hand.

Upskill and retain talented employees

Equip your team for the future. Integrated training and knowledge tools facilitate efficient upskilling in new processes. Standardized best practices and accessible knowledge empower every frontline worker with the insights needed to excel.

See it in action!

Results from automotive companies

"L2L offers data at an extremely intuitive level. It’s actionable data. The report structures are so easy to manage that it allows for very easy determinations of cause and effect around failures."

- +10% increase in OEE

- 120x faster data analysis

- Improvements in OA, with some areas reaching 90%

- First Pass Yield increased

Features & Capabilities

Discover L2L's powerful features and functionality designed to streamline your operations, enhance team performance, and drive tangible results.

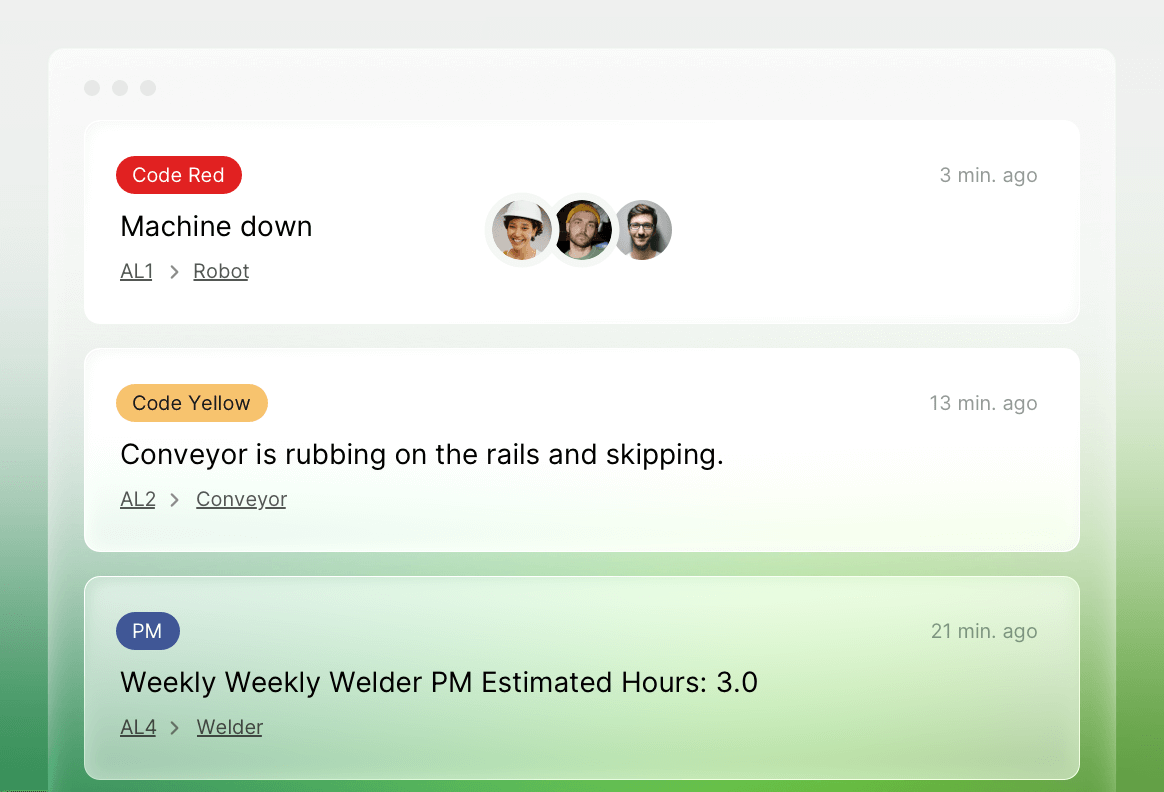

Dispatch issue resolutions

Reduce downtime with immediate production issue reporting. Centralized data lets you automatically alert the right people with the right information for rapid issue resolution.

Work order management

Plan work around production and maintenance schedules to maximize equipment availability and minimize disruptions.

Preventive maintenance

Schedule routine and preventive maintenance based on time intervals or equipment usage cycles.

Suggested fixes

Intelligent AI capabilities will suggest correct spare parts or resolutions based on previous correct fixes.

Spare part tracking

Use a centralized system for managing spare part details like cost, images, machine association, min/max quantities, and location.

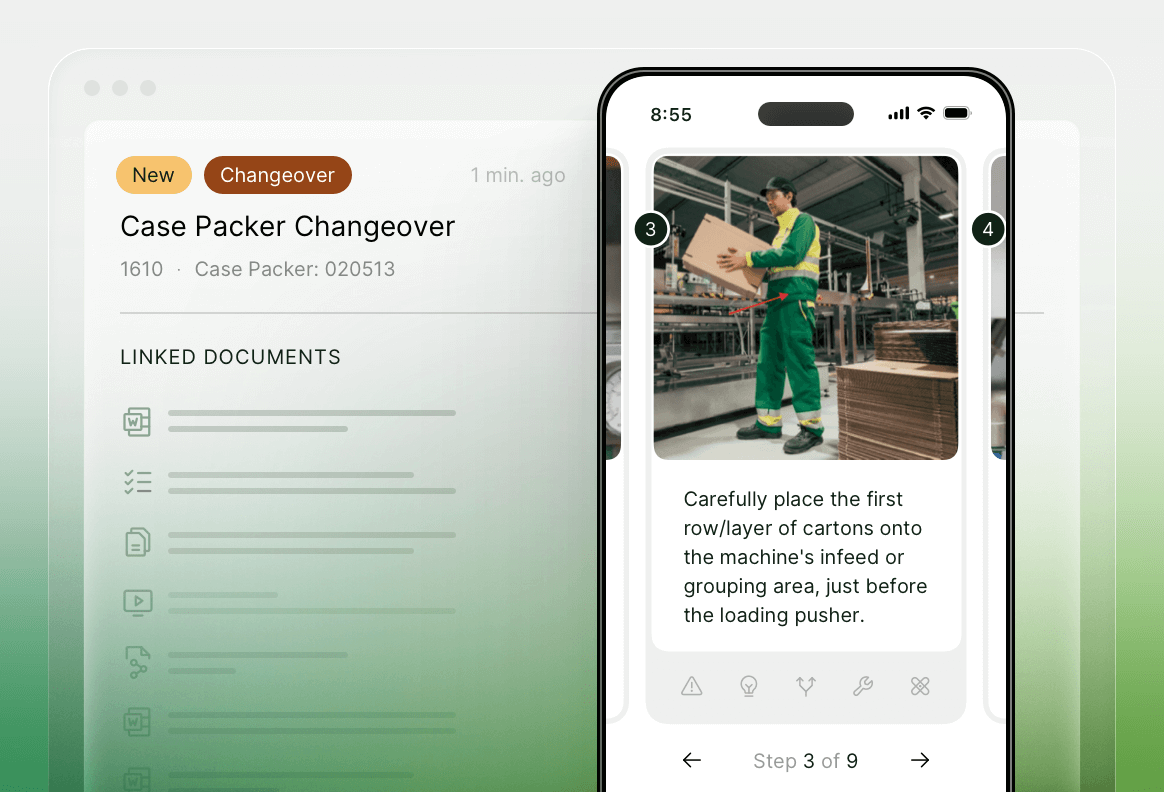

Digital work instructions

Follow clear, step-by-step visual work instructions to quickly resolve issues and empower frontline employees.

Key metric monitoring

Track production metrics like status by site, OA, scrap quantity, run rate, downtime, OEE, yield, and more.

Production scheduling

Coordinate production schedules, maintenance schedules, audits, gemba walks, and more all in one system to maximize availability and meet demand.

Changeover management

Seamless and standardized changeover management with digital instructions to improve quality and reduce reworks.

Quality management

Ensure quality standards are met with digital work instructions, streamlined changeover processes, and effective frontline upskilling.

Data-driven insights

Make data-driven decisions by recording and tracking key metrics or KPIs.

Real-time notifications

Streamline communication and ensure employees receive real-time notification of ongoing issues.

Ready to improve output and efficiency?

Transform your manufacturing floor with L2L. Gain complete visibility, streamline processes, and empower data-driven decisions for significant improvements in output and efficiency.

Explore the power of L2L today.

_EasiestSetup_EaseOfSetup.png?width=869&height=1000&name=AdvancedPlanningandScheduling(APS)_EasiestSetup_EaseOfSetup.png)