Unlock peak production performance

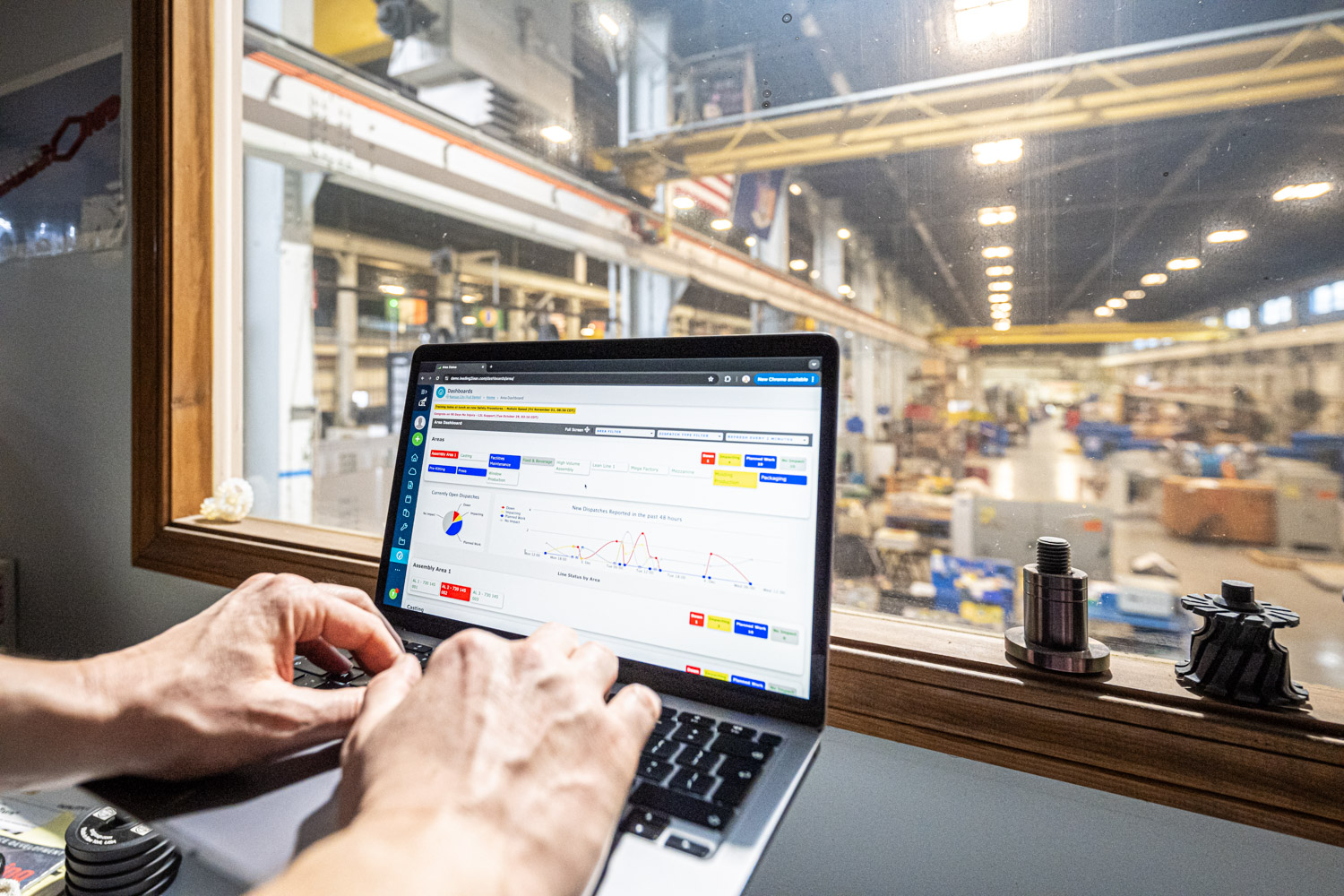

Gain real-time production visibility and control over your production floor with L2L’s Manufacturing Execution System (MES). Optimize production scheduling, minimize waste, and ensure product quality.

Trusted by global manufacturing leaders

Built by manufacturing experts for manufacturers.

L2L is more than a typical MES. Centralize your plant operations in one place. Manage downtime tracking, maintenance activities, production goals, and frontline knowledge and skills. Gather comprehensive data to drive continuous improvement.

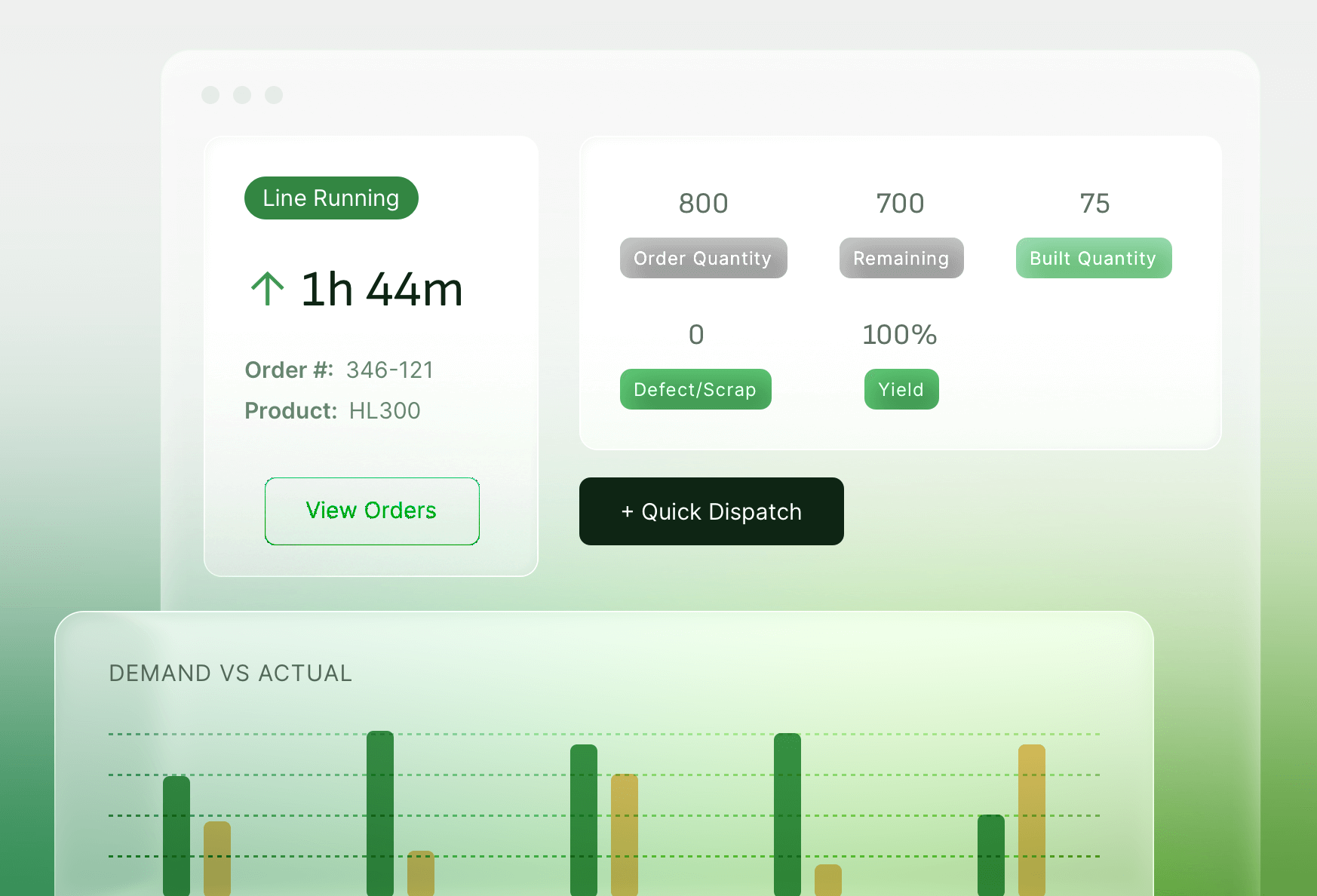

Real-time production floor visibility

Gain real-time visibility into your production floor. Immediately view status and performance metrics for different lines, report issues right away, and ensure you’re meeting production demand.

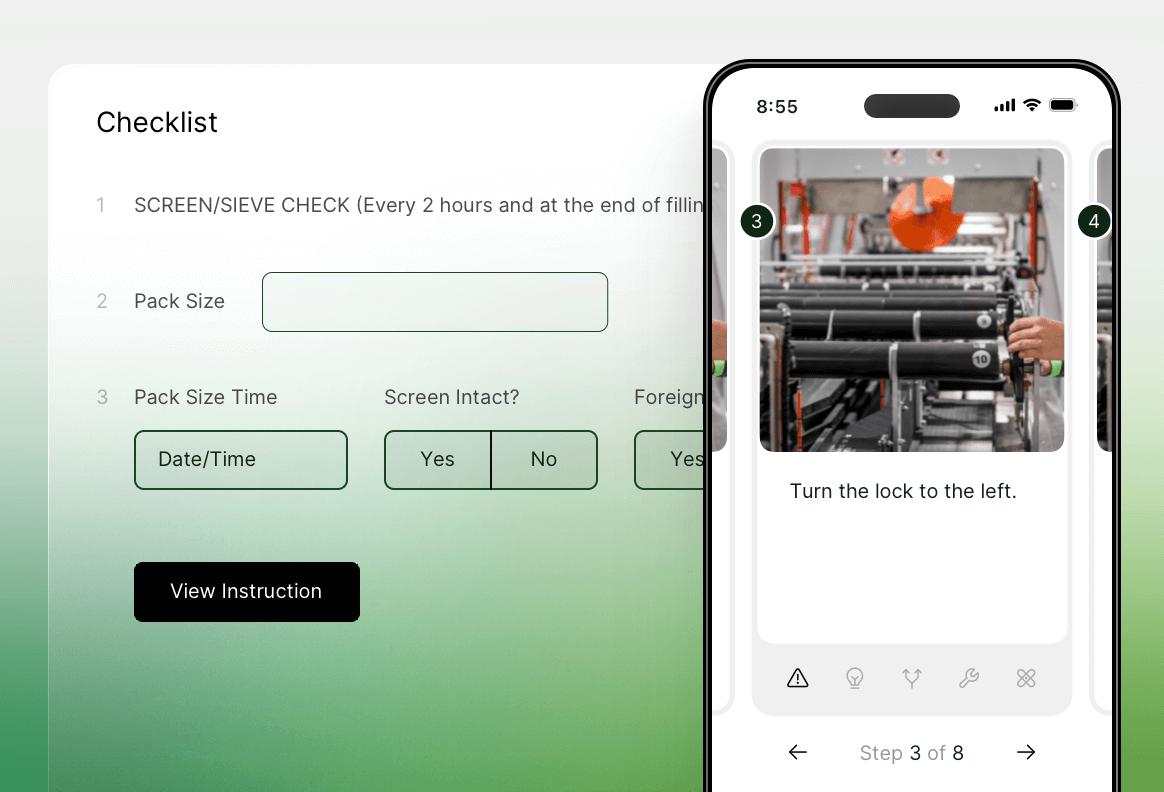

Ensure product quality. Eliminate defects.

Standardize best practices like changeovers, quality checks, and more with digital guides. Identify, report, and resolve issues, minimizing waste and ensuring products meet quality standards.

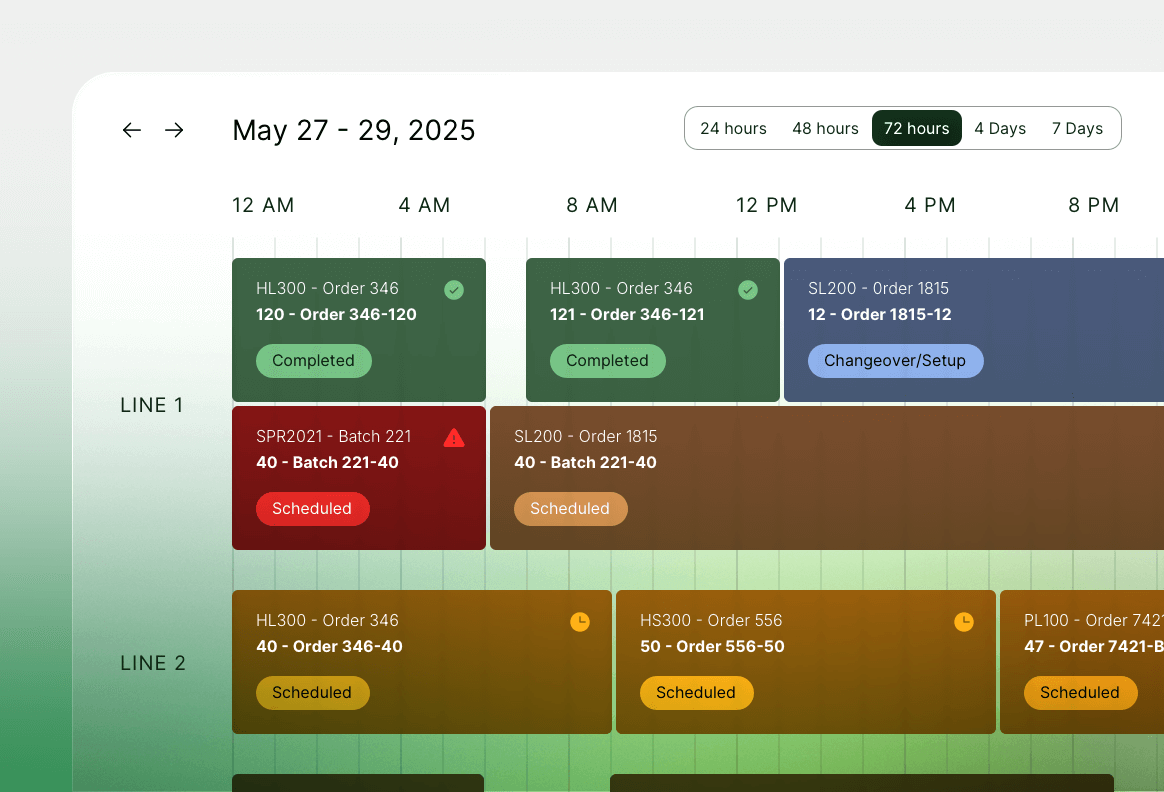

Efficiently allocate resources

Optimize your production schedule with comprehensive planning tools to meet demand. Proactively mitigate bottlenecks and ensure on-time delivery, maximizing resource utilization and customer satisfaction.

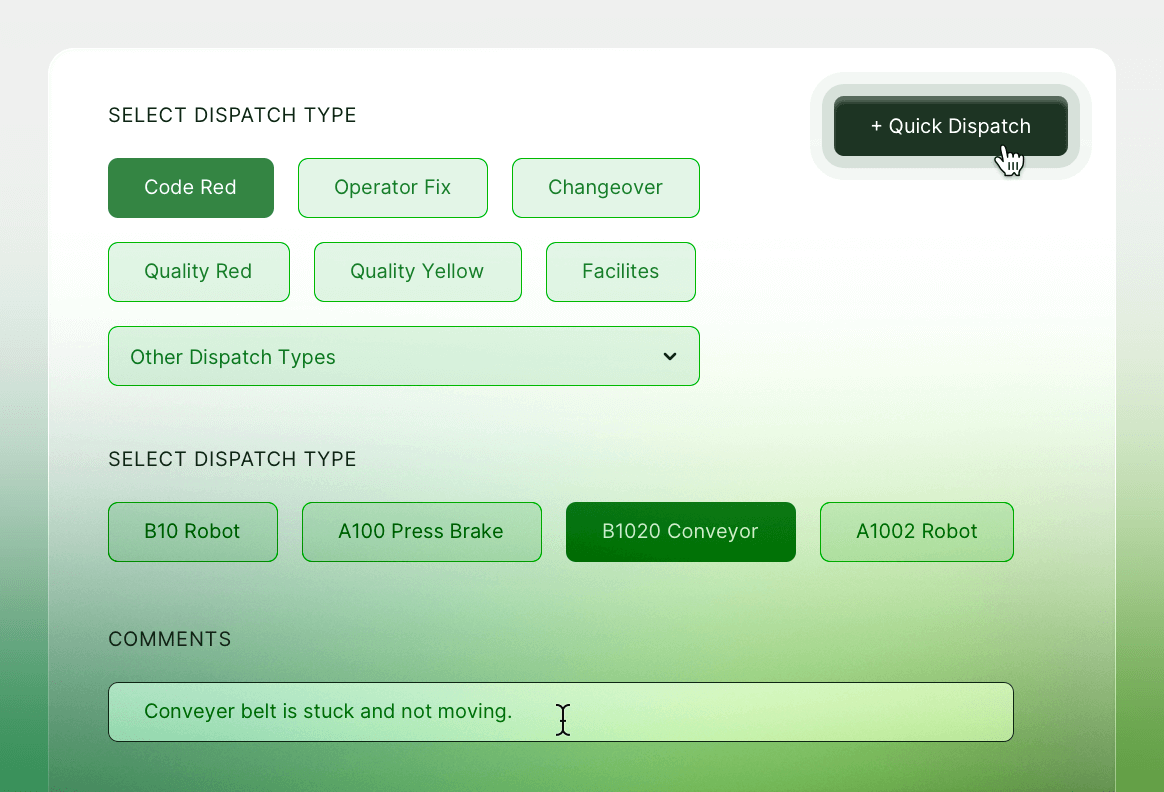

Maximize uptime and minimize disruptions

Proactively schedule maintenance to increase asset uptime and prevent costly unplanned downtime. Empower your team to quickly report issues and ensure efficient resolution by automatically escalating problems to the appropriate technicians.

Manufacturing Execution System ROI

Manufacturing Execution System (MES)

Discover L2L's powerful features and functionality designed to streamline your operations, enhance team performance, and drive tangible results.

Want to learn more? Read our guide.

Dispatch issue resolutions

Empower your team to immediately report production issues, automatically alerting the correct personnel with centralized data and proven fixes for rapid resolution and reduced downtime.

Digital work instructions

Follow clear, step-by-step visual work instructions to quickly resolve issues and empower frontline employees.

Maintenance management

Report, resolve, and track reactive and proactive maintenance initiatives while taking into account production schedules.

Key metric monitoring

Track production metrics like status by site, OA, scrap quantity, run rate, downtime, OEE, yield, and more.

Production scheduling

Coordinate production schedules, maintenance schedules, audits, gemba walks, and more all in one system to maximize availability and meet demand.

Document management

Centralized access to critical documents (PDF Manuals, Gemba Walks, Product Drawings, etc.).

Quality management

Ensure quality standards are met with digital work instructions, streamlined changeover processes, and effective frontline upskilling.

Integrated systems

Integrate L2L with existing systems, including your ERP, QMS, PLM, SCM, or CMMS.

Resource management

Centralized system for managing assets, machines, spare parts, and tooling.

Real-time notifications

Streamline communication and ensure employees receive real-time notification of ongoing issues.

Digital checklists

Create dynamic checklists to ensure tasks are followed to the standard and record information.

Changeover management

Seamless and standardized changeover management with digital instructions to improve quality and reduce reworks.

See it in action!

Improved quality and throughput

Easy access to checklists and standardized documentation increases quality and saves time.

Reduced waste and scrap

Better data and visibility have illuminated where issues were occurring and helped reduce scrap and rework.

What makes L2L so unique is the fact that the product was developed by real manufacturing users. People that truly understand the day-to-day issues and concerns that drive the production floor.

Lean Maintenance Consultant

Everything our plants could do to improve efficiency, reduce unplanned downtime, drive waste out of the process, and react faster to change are becoming even more critical to keep up with the changing market conditions.

VP of Operations

With L2L, ADAC captures and details hundreds of operational activities every day: from lab samples and first part checks to preventative and reactive equipment maintenance, calibrations, and beyond.

Vice President of Quality

Explore our customer success stories.

Don't just take our word for it, see how other manufacturers are achieving results with L2L.

Frequently asked questions

How does L2L help improve production performance?

L2L empowers teams with real-time visibility into operations, data-driven insights, and tools to quickly address production disruptions and waste. From tracking OEE to managing production schedules, L2L is designed to maximize throughput and efficiency at every level.

Which performance metrics does L2L track?

How does L2L help reduce defects and improve quality?

L2L enables clear visibility to quality issues with real-time monitoring, in-process inspections, and root cause analysis. These tools help teams identify and resolve problems quickly to reduce waste and improve product quality.

Can I connect L2L to other systems?

Yes, L2L can be connected to most other systems. Our Technical Services team provides seamless integration setup and maintenance.

How long does implementation take?

We pride ourselves on an efficient, scaled implementation approach. Go-live can happen in as little as a few weeks, so you can begin realizing value from L2L.

Ready to improve output and efficiency?

Transform your manufacturing floor with a modern MES. Gain complete visibility, streamline processes, and empower data-driven decisions for significant improvements in output and efficiency.

Explore the power of L2L today.

_EasiestSetup_EaseOfSetup.png?width=869&height=1000&name=AdvancedPlanningandScheduling(APS)_EasiestSetup_EaseOfSetup.png)