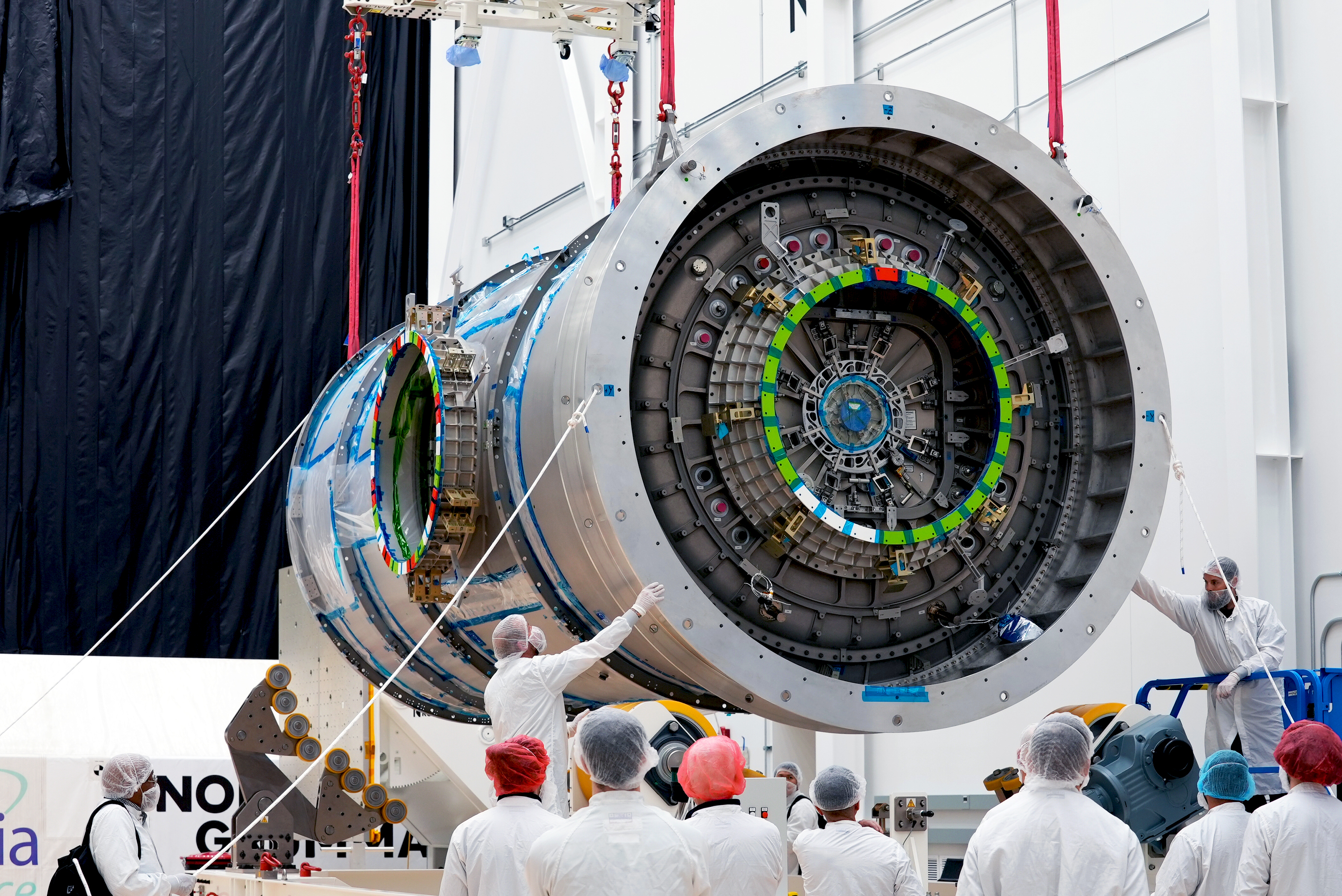

Northrop Grumman Saves Millions with L2L

Northrop Grumman Corporation is a top-tier aerospace and defense technology company.

With L2L, Northrop Grumman has:

-> Significantly increased operational availability

-> Boosted production capacity

-> Dramatically reduced labor costs

-> Achieved compliance with government preventative measures

.png)

Northrop Grumman x L2L achievements

Labor cost reduction

Northrop Grumman implemented L2L in order to become more efficient and competitive.

Before

Northrop Grumman needed to lower product and maintenance costs to effectively re-compete for the award of a government-owned munitions plant. The plant needed to deliver a quality product at a significantly lower cost.

Now

The company reduced maintenance labor costs by over 60% in the first year, with an additional 40% reduction in the second year. This dramatic cost reduction significantly improved competitiveness for government contracts while maintaining product quality.

With the L2L Dispatch system in this plant, they're setting the pace for the rest of this company.

Production capacity optimization

L2L helped Northrop Grumman achieve substantial production increases through process improvements.

Before

The facility faced challenges in maximizing production output while meeting strict government requirements and managing costs effectively.

Now

Northrop Grumman increased production by 50%, creating significantly more output with the same equipment and facilities. This dramatic improvement was achieved while simultaneously reducing labor costs, creating exponential improvements in productivity and efficiency.

We've tried literally dozens of other solutions, CMMS, and attempts at lean programs in the past 28 years, but this is the first one I've seen truly make a difference.

Operational availability improvement

With L2L, Northrop Grumman significantly improved OA while maintaining its focus on cost reduction.

Before

Meeting government-required preventative maintenance measures while controlling costs posed significant challenges, often resulting in reduced operational availability.

Now

Operational availability increased by 38% in just six months. Detailed data solved recurring problems and optimized preventive maintenance efforts. Real-time transparency into resource engagement drove immediate accountability while supporting cost reduction goals.

The return on investment

Labor costs ↓

60% reduction in labor costs in their first year with L2L & 40% additional reduction in labor costs in their second year with L2L

Production ↑

Operational availability ↑

38% increase in OA

Cost savings ↑

Competitive edge ↑

Compliance ↑

The solution that shows your manufacturing problems—and fixes them too

Drive continuous improvement in availability, performance, quality, and workforce enablement.

Quickly identify problems and take action faster with L2L. Empower your teams to achieve daily wins and drive success every day.

Trusted by leading sites around the globe.