You may be asking, “My what, now?”

Your data sandwich is a way to think about all the systems your company uses to streamline manufacturing processes.

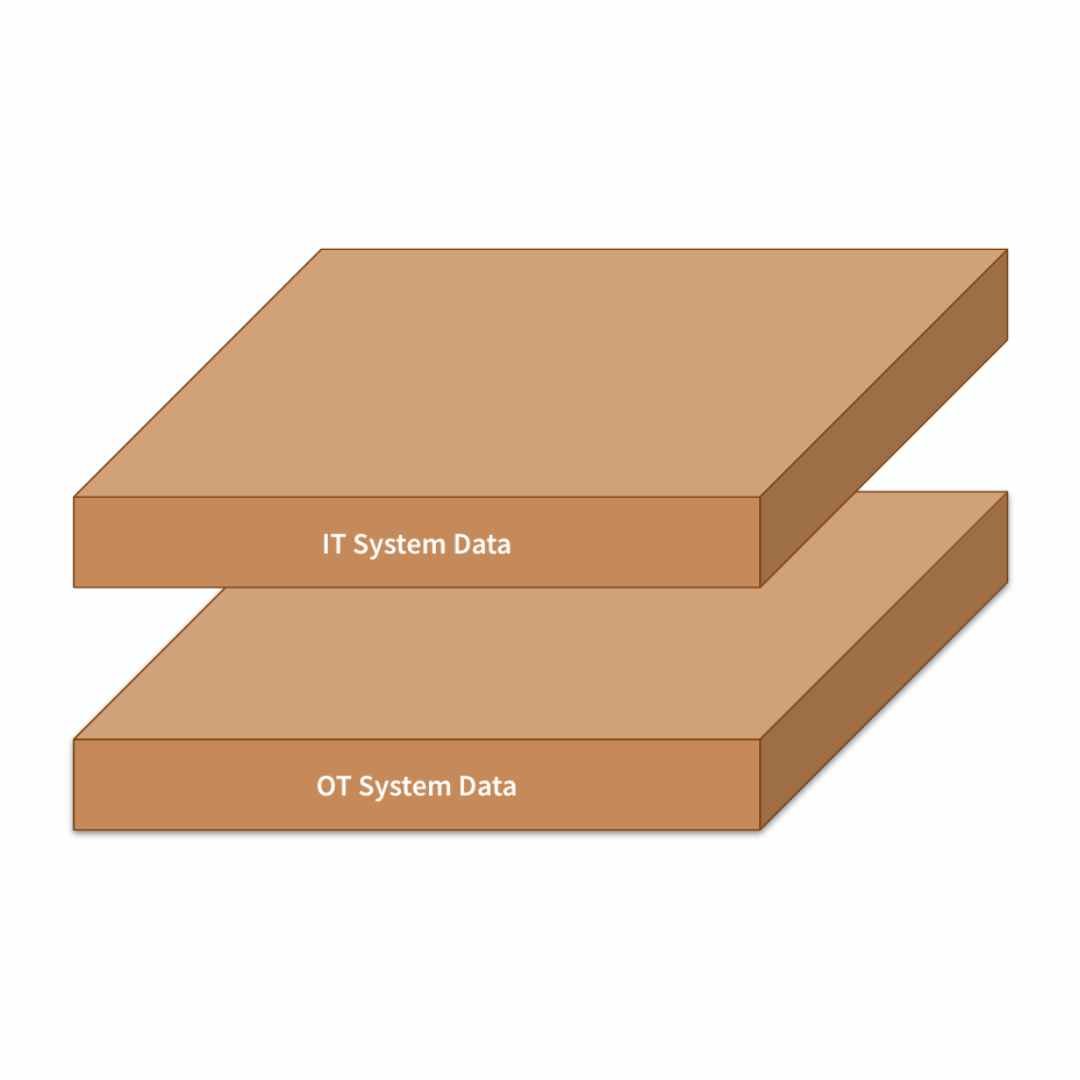

A typical data sandwich might look like this:

On the top layer, you have your IT systems that support individual departments:

-

Operations has their MES to guide productivity

-

Maintenance has their CMMS to guide reliability

-

Quality has their QMS to improve product quality

-

EH&S has systems to monitor safety and regulatory compliance

-

You may have an ERP tucked in there too, with a broader purpose

On the bottom layer, you have your Operational Technology. It monitors machine, process, and sensor data, which helps you understand machine activity and line health.

But what good is a two-layer sandwich? Have you ever thought “Mmm … I need to get myself a bread sandwich.”

Nope, me neither.

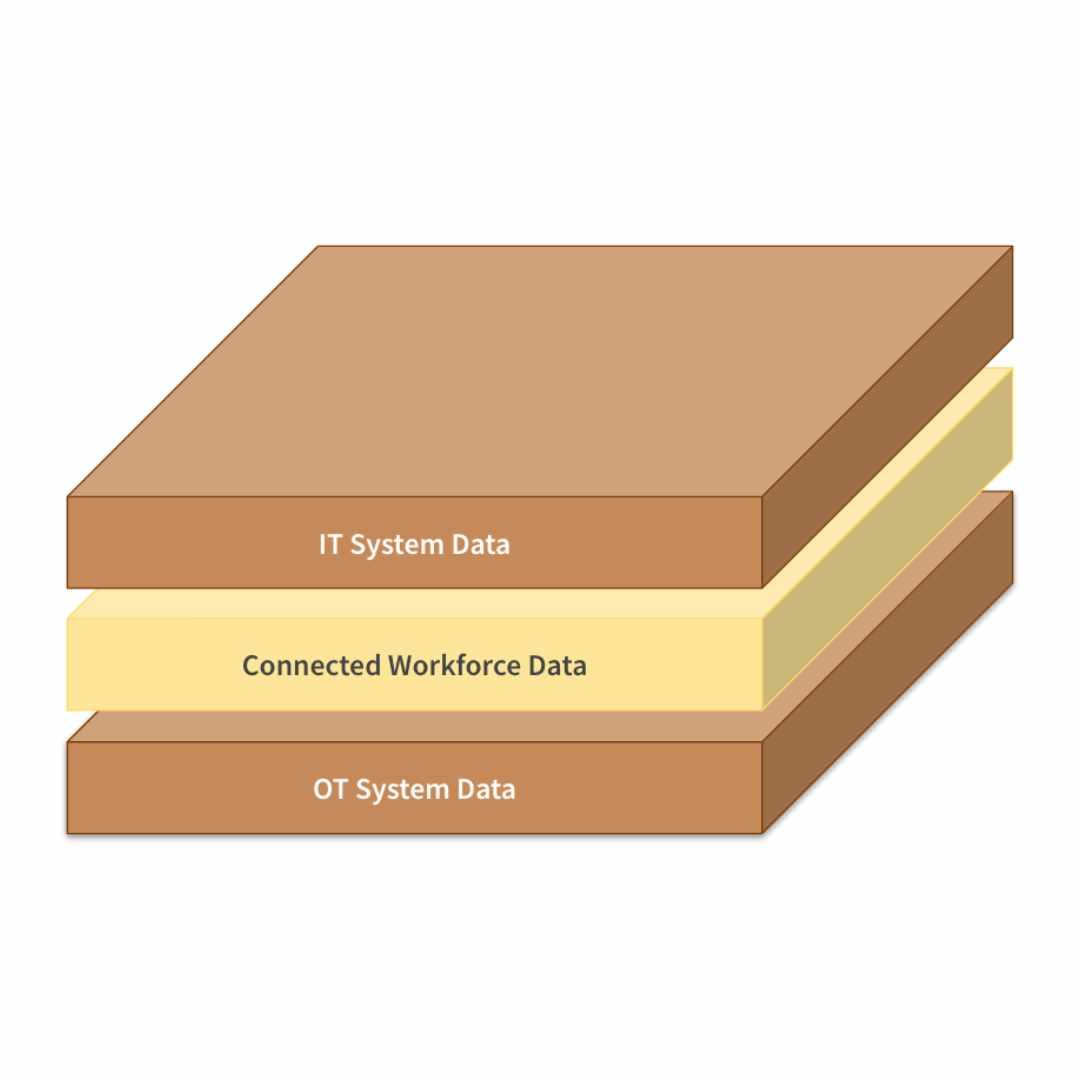

What makes a sandwich delicious is what’s in the middle. Maybe it’s pulled pork, peanut butter and jelly, or straight-up ham and cheese. Maybe you like condiments or you’re one of those pickle people.

The point is that the bread is a given: You need it to make a sandwich. It gives your sandwich stability, not character.

And for manufacturers, the best middle layer of their data sandwich is connected workforce data. This is where the magic happens.

Connected workforce data tells you what’s happening on the shop floor right now, across any manufacturing dimension: people, process, material, or machine. And unlike IT or OT data, this data is generated by, consumed by, and turned into action by frontline workers.

Connected workforce data can take many forms:

-

Dynamic work instructions that help maintenance techs perform jobs the right way — even if it’s for the first time

-

Digital Andon to alert colleagues when there’s a problem

-

Condition-based workflows that dispatch workers to perform tasks before they morph into downtime events

-

Escalations, alerts, and real-time collaboration to solve complicated problems

Connected workforce data is where the value add happens. We’ve seen too many companies so distracted by maintaining IT and OT systems that they neglect to add value to how products are actually made. Remember, without shop floor processes there are no products, and without products, there is no company.

Connected workforce data is the secret ingredient to your data sandwich that unifies the entire shop floor team, providing them with real-time visibility so they take action faster. Faster action means higher productivity, better quality, and less unplanned downtime. Plus, frontline workers prefer employers that invest in systems that help them perform at their best.

Have you tasted your data sandwich lately?

For more on the data sandwich concept, check out our latest episode of The Manufacturing Stream podcast!

Revisions

Original version: 15 January 2024

Written by: Malcolm Faulds

Reviewed by: Daan Assen

Please read our editorial process for more information

Related Posts

Subscribe to Our Blog

We won't spam you, we promise. Only informative stuff about manufacturing, that's all.