4 min read

L2L and Dart Container Recognized as Finalists for the 2024 Manufacturing Leadership Awards

The partnership provided double-digit improvements to Dart’s OEE and set the stage for a pilot facility to enjoy its...

March 04, 2021

New Customers include Oetiker-Germany, Nissin Brake, Worthington, ADAC, Hanon and ZF

SPARKS, Nev. — Mar. 4, 2021 – The negative impacts of 2020 are still being felt in industries across the globe. The COVID-19 pandemic took a major toll on manufacturing and the automotive industry was no exception. According to the Boston Consulting Group, 2023 is predicted to be the year when automotive sales in Europe and U.S. will return to pre-COVID levels. Until then, the industry has been adapting and has been pushed to quickly become more automated, digitized, and find ways to increase efficiency.

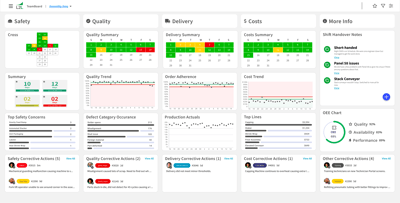

Greater efficiency and visibility have become key factors in allowing the automotive industry to adapt. This is true from the plant floor to the C-Suite, and to customer transactions. Many manufacturers have found that L2L, a leading provider of plant floor digital lean production and maintenance solutions for manufacturers, has provided them real-time visibility, workflow management, reduced downtimes, and the need for fewer people on-site to allow for social distancing precautions.

As more automotive manufacturers realize these benefits from L2L’s cloud-based plant floor solutions, L2L’s automotive customer base continues to grow. Despite 2020 being a challenging year for the industry, the following are a few automotive companies where new manufacturing sites were added during the year:

“Though the past year has been challenging for everyone, we have been proud to be able to help our customers adapt and continue doing business successfully,” said Bob Argyle, CCO of L2L. “Our system, uniquely, can be quickly and inexpensively deployed, tailored for each manufacturer’s needs, and has become a critical tool for managing operations both on-site and remotely.”

L2L’s technology has a history of proven results with companies like Autoliv. In 2018 Autoliv achieved a 5% global improvement in operational availability, 30% in faster response time to equipment hurdles, and 12% cost reductions after deploying L2L. More recently, new customer ADAC saw a 211% decrease in downtime in one facility, and a 113% decrease in a second facility during 2020.

L2L’s momentum has steadily grown over the past 24 months. The company’s achievements over that time included an award by the National Association of Manufacturers’ (NAM) Manufacturing Leadership Council, recognizing L2L’s role in Purple Innovations’ manufacturing success.

To learn more about L2L and how you can deploy our system, please visit www.L2L.com.

About L2L

Founded in 2010, L2L provides a Lean Execution System software platform for manufacturers. It has integrated and easy-to-use lean tools that allow operators and managers to use real-time data to reveal and solve root cause problems that cause metric misses, all while creating a sustainable plant floor culture of continuous improvement. For more information, visit www.L2L.com.

Apr 11, 2024by L2L

The partnership provided double-digit improvements to Dart’s OEE and set the stage for a pilot facility to enjoy its...

Feb 8, 2024by L2L

Kyle Petty to Keynote the Annual User Conference in May

SALT LAKE CITY, Utah, February 8, 2024 - L2L, the global...

Sep 6, 2023by Trent Johnson

Salt Lake City, UT – September 6, 2023: L2L, the Connected Workforce pioneer, is excited to announce the highly...

What makes L2L so unique is the fact that the product was developed by real manufacturing users. People that truly understand the day-to-day issues and concerns that drive the production floor.